Index revision : A

37

7145

10. Communication with the PLC in CAN

10.1. Characteristics

In CAN mode a PLC manages the display and/or control of the data of the INOBOX module.

It is necessary to configure the address of the Inobox and the communication speed (from 0 to

7) using the setting screen.

10.2. Data exchange

10.2.1. From CAN to the Inobox module

8 bytes are exchanged from a CAN module to the Inobox

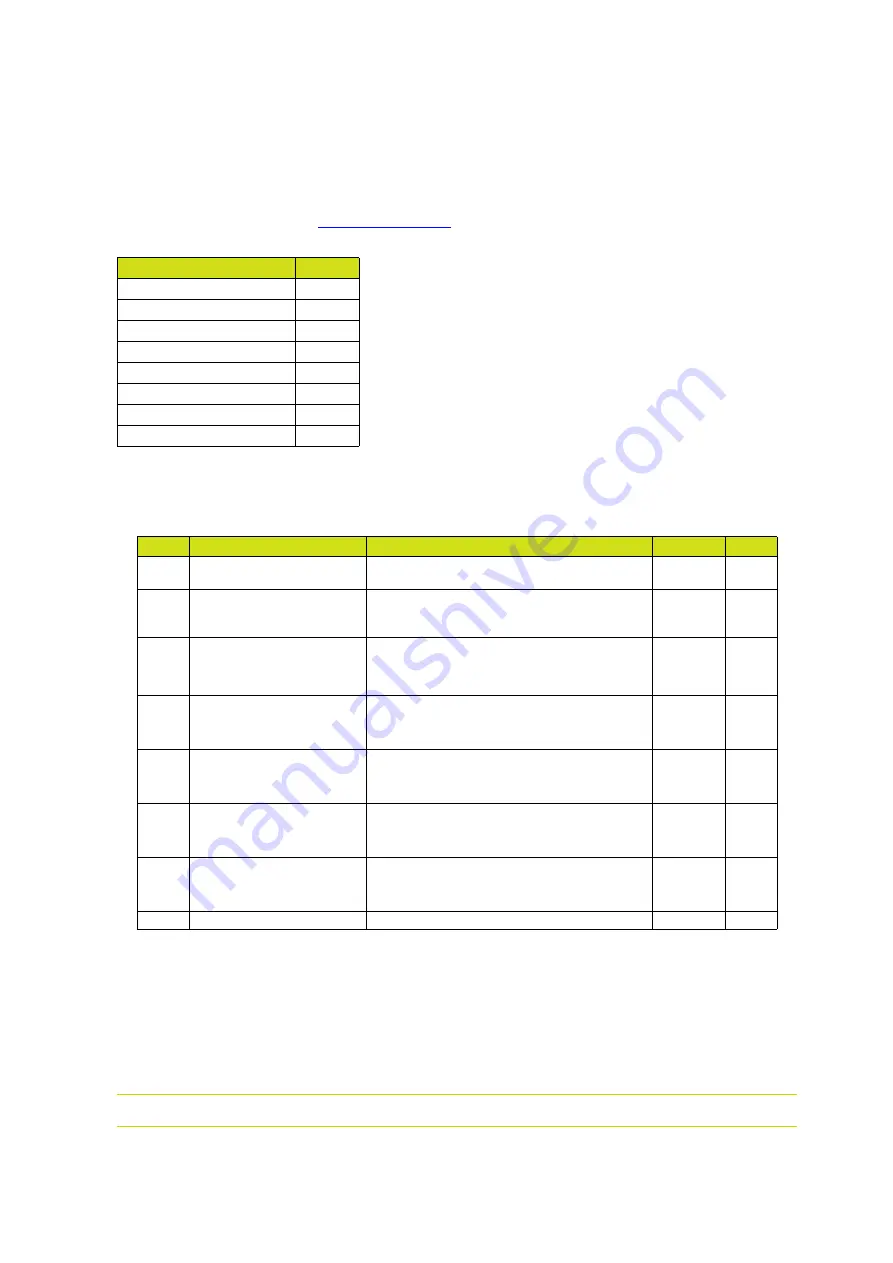

Speed in Kbits/s

10

0

20

1

50

2

100

3

125

4

250

5

500

6

1000

7

Byte

Label

Description

Unit

Max.

0

CAN Command

Commands requested by the CAN (see the

detailed description hereafter)

-

1

CAN Current Setpoint

Current setpoint requested by the CAN.

This setpoint is applied only if the CAN_Control

mode is active and the HV trigger is activated

µA

110

2

CAN Voltage Setpoint

High voltage setpoint requested by the CAN.

This setpoint is applied only if the CAN_Control

mode is active and the HV trigger is activa-

ted.

kV

100

3

CAN Injection Setpoint

Injection setpoint requested by the CAN.

This setpoint is applied only if the CAN_Control

mode is active and the HV trigger is activa-

ted.

Point

100

4

CAN Dilution Setpoint

Dilution setpoint requested by the CAN.

This setpoint is applied only if the CAN_Control

mode is active and the HV trigger is activa-

ted.

Point

100

5

CAN Blowing Setpoint

Blowing setpoint requested by the CAN.

This setpoint is applied only if the CAN_Control

mode is active and the HV trigger is activa-

ted.

Point

30

6

CAN Fluidisation Setpoint

Fuidisation setpoint requested by the CAN.

This setpoint is applied only if the CAN_Control

mode is active and the HV trigger is activa-

ted.

Point

50

7

Spare