23

OPERATOR'S MANUAL

HYDRAULIC FRONT-LOADER EXTENSION

ARM

FISHER

7.

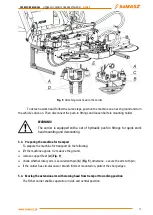

MAINTENANCE AND SERVICE

Tab. 2.

Torque values for bolts

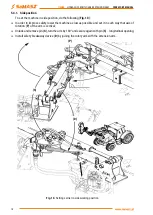

8.

MALFUNCTIONS AND THEIR REPAIRS

In the event of a malfunction, immediately stop the machine and after the cutting assembly has

come to a complete stop, turn off the engine. Before disconnecting any of the hydraulic hoses, check

whether there is no pressure in the hydraulics and remember to cut-off the oil feed from the tan to the

machine's hydraulics. Hot or/and pressurized oil leak may cause serious bodily injuries. For the

machine's operator safety, stop the machine on an even ground. All hydraulic cylinders and moving

elements must be completely locked.

Defect

Reason

Repair

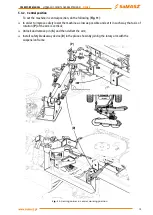

Shift cylinder cannot be

operated.

Hydraulic connectors are not

connected to one pair of feed

connectors.

Connect hydraulic connectors correctly.

Hydraulic connectors are not

compatible with hydraulic

connectors on the vehicle.

Replace the connectors for correct ones.

Closed choke valve on the cylinder

(speed adjustment).

Adjust choke valve.

Rotation cylinder cannot

be operated, although

extension cylinder works

correctly.

Control panel not connected.

Check if after the controller activation the

LED indicators are lit, check lighter outlet

and 3-pin plug at the machine. Make sure

that electric cables are not cut.

Damaged solenoid.

Check if coil on the valve operates correctly.

Otherwise, replace the coil.

Replace the solenoid.

Vibrations and noises

when extending the arm.

No lubrication.

Lubricate the slides in suspension frame.

Rotary arm is lifting too

often.

Damaged safety breakaway

device.

Replace safety breakaway device if force

applied to the head, at which the arm is

lifted is less than 8000N.