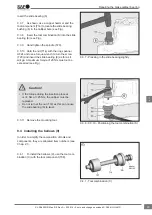

10.2.4 Locate the diaphragm chamber (see Fig.).

Note: To prevent the diaphragm chamber from

tilting whilst being tightened, the new self-locking

hex nuts of the diaphragm chamber must be hand

tightened symmetrically with a suitable tool.

10.2.5 Tighten both self-locking hex nuts in

accordance with the information from the brake

chamber manufacturer.

10.2.6 Tighten the brake hose to the diaphragm

chamber, ensuring that the hose does not twist and

is routed such that chafing cannot occur!

10.2.7 Check that the air connection is leak tight.

Perform a function and effectiveness check of

the BBA!

Danger !

10.3 Removing the combined chamber

Before loosening the combined chamber, secure

the vehicle to prevent it from rolling away.

Danger !

10.3.1 Release the parking brake.

10.3.2 Move the spring mechanism emergency

release spindle (arrow D) to the release position

(observe the regulations from the vehicle manufac-

turer) (see Fig.).

10.3.3 Actuate the parking brake.

10.3.4 Unscrew the air connections from the com-

bined chamber (18) (the connection line must be

depressurised).

10.3.5 Unscrew both self-locking hex nuts from

the combined chamber (18) and remove the com-

bined chamber (18) (see Fig.).

Unscrew the hex nuts from the combined

chamber (18) and do not re-use.

Danger !

11.2.4 - Locating the diaphragm chamber

11.3.2 - Moving the spring mechanism emergency

release spindle to the release position

11.3.5 - Removing the SAF-HOLLAND combined

chamber

Replacing the brake chamber

47

en

XL-SA40001RM-en-DE Rev A • 02.2016 • Errors and changes excluded © SAF-HOLLAND