7.3

Mounting the pressure fittings with

bellows (13)

The pressure fittings are supplied with special long-

term lubrication and a protective cap.

Before mounting, the protective cap must be

removed and properly disposed of. The grease

must not be smeared or removed.

Grease contamination onto the bellows or other

components must be avoided. In addition,

additional greasing of the pressure fittings with

other lubricants is not permitted.

With the brake calliper installed:

7.3.1

The pressure fittings (13) must be mounted

with the tool combination (E1) shown (see Fig.).

7.3.2 Fully turn back the threaded pipes (16) with

the adapter (61) (see Chap. 6.1.4).

Note: The seal for the bellows in the brake calliper

must be clean and free of grease.

7.3.3 Fit the new slide bearing bushing (161) to

the threaded pipes (16) and fit the pressure fitting

with bellows (13) to the base of the threaded pipe

(16).

7.3.4 Position the tool combination (E1) and

mount the pressure fitting (13) to the threaded pipe

by unscrewing the tool component (T03).

Note: The tool component (T55) is not required for

this mounting step.

7.3.5 Turn the tool combination (E1).

Note: Before performing the next step, insert the

tool component (T55) into the tool component

(T28).

7.3.6 Unscrew the threaded pipes with the adapt-

er (61) 2 turns and move the tool component (T28)

into position centrally as shown.

7.3.7

Press in the bellows of the pressure fitting

(13) with the tool component (E1) (see Fig.).

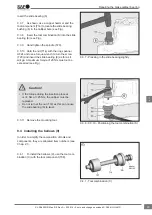

7.3.1 - Tool combination E1

7.3.7 - Pressing in the bellows with the tool

component (E1)

7.3.3 - Mounting the

slide bearing bushing

and pressure fitting

with bellows to the

threaded pipes

7.3.4 - Pressing in the

pressure fitting with the

tool combination (E1)

Replacing the pressure fittings

31

en

XL-SA40001RM-en-DE Rev A • 02.2016 • Errors and changes excluded © SAF-HOLLAND