Instruction manual V 2.3

37

PWM 230 - PWM 400 - PWM 400/7.5

Instruction manual

-

Maximum frequency limiting as temperature increases over a potentially dangerous value

The second type of protection is used on:

- power

devices

- supply

capacitor

- printed

circuit

It acts when a potentially dangerous temperature is reached, by gradual decrease of the maximum

frequency of rotation FS. The purpose is that of reducing power dissipation thus protecting the PWM against

overheating. Once the alarm cause disappears, the protection is automatically disabled and normal

operation conditions are restored. Intervention of one or more of these protections can only decrease the

frequency FS by no more than 20%.

The three protection systems don't cause a block and don't produce any error message, but keep track of

their intervention by insertion of an alarm in the fault history (see sec. 5.2.2.7).

Note:

during intervention of such protections a FR frequency of rotation smaller than the expected one

could be displayed.

If the temperature of the final output stage or of the printed circuit is not successfully limited by the

mentioned protections, an overtemperature blockage will occur.

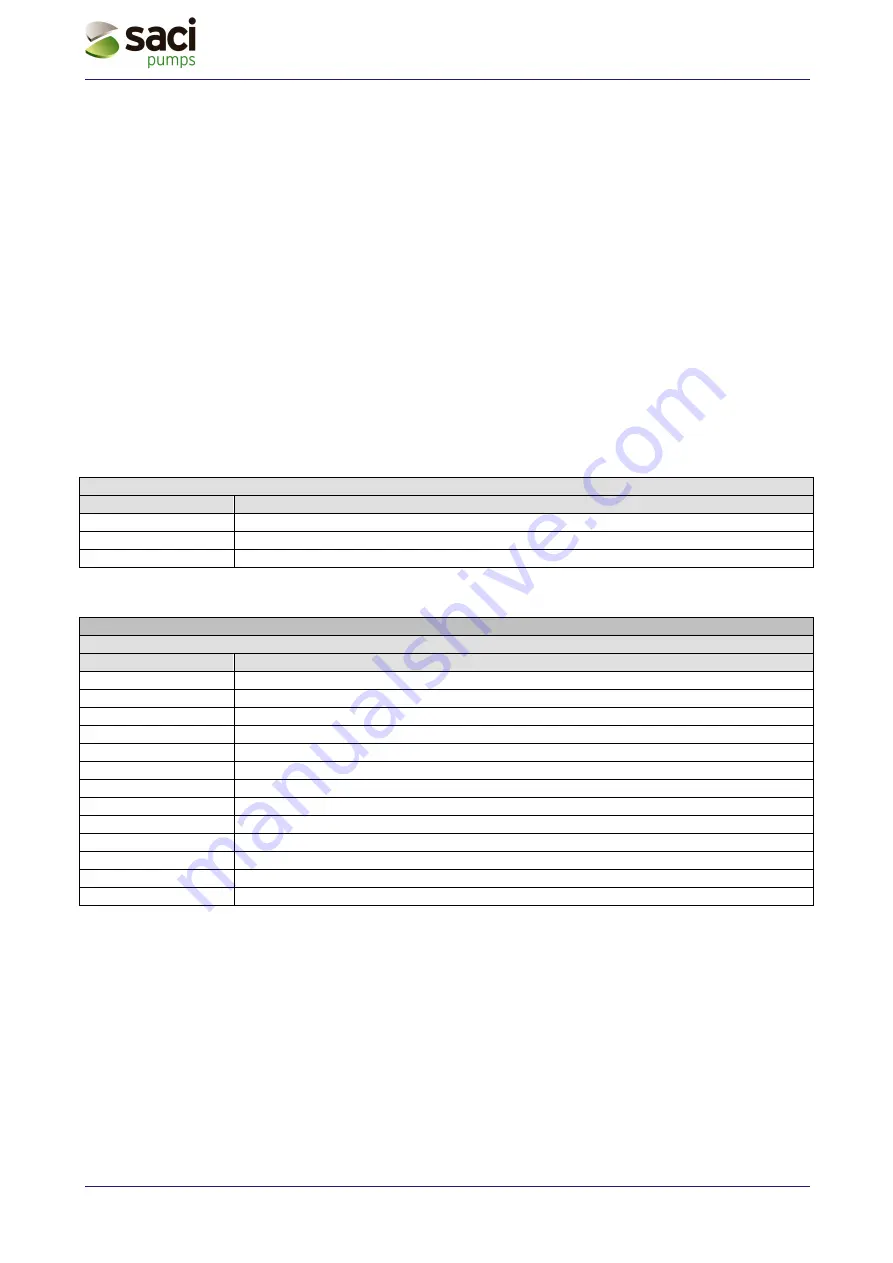

Warning on the fault history queue

Display indications

Description

Lt

Overtemperature on the power devices alarm (tE > 85°C)

LC

Overtemperature on capacitor alarm

Lb

Overtemperature on printed circuit alarm (bt > 100°C)

Table 12: Warning on the fault history queue

Error conditions

Error and status conditions

Display indications

Description

bL

Blockage due to lack of water

bP

Blockage due to disconnected pressure sensor

LP

Blockage due to low supply voltage

HP

Blockage due to high rectified voltage

Ot

Blockage due to overheating of the power output stages (tE > 100°C)

Ob

Blockage due to overheating of the printed circuit (bt > 120°C)

OC

Blockage due to overcurrent in the electro pump motor

OF

Blockage due to overcurrent in the output stages

SC

Blockage due to direct short circuit between the phases of output terminals

EC

Blockage due to incorrect setting of the rated current (rC) or rated frequency (Fn)

E0...E7

Blockage due to internal error 0...7

F1

Status / Blockage due to input 1 status

F3

Status / Blockage due to input 3 status

Table 13: Error conditions

“bL” Blockage due to lack of water

In no flow conditions the system turns off the pump. If the pressure is lower than the set point one, the

display shows a lack of water message.

If you wrongly set a pressure set point higher than the pressure that the electro pump is able to supply, the

system will sign “lock due to lack of water” (bL) even if there is no lack of water. So you should lower the set-

point pressure at a reasonable value that usually does not exceed 2/3 of the of the installed electro pump’s

head.

Note: The PWM system operates at constant pressure. This regulation is appreciable if the hydraulic

system downstream from the system is properly sized. Systems with too narrow pipes lead to a