Input and Output Signals

Publication PUB091-004-00_0918

25 of 64

5

THE ACTUATOR INPUT AND OUTPUT SIGNALS

The MFU allows the actuator to be controlled by, and to report data to, a suitable host device using

Modbus RTU protocol. This section explains the data signals that are available for exchange and their

meaning in relation to the actuator functionality. The data locations used for the Modbus registers and

coils are given later in this manual.

This section also gives information on the other control inputs available for moving the actuator.

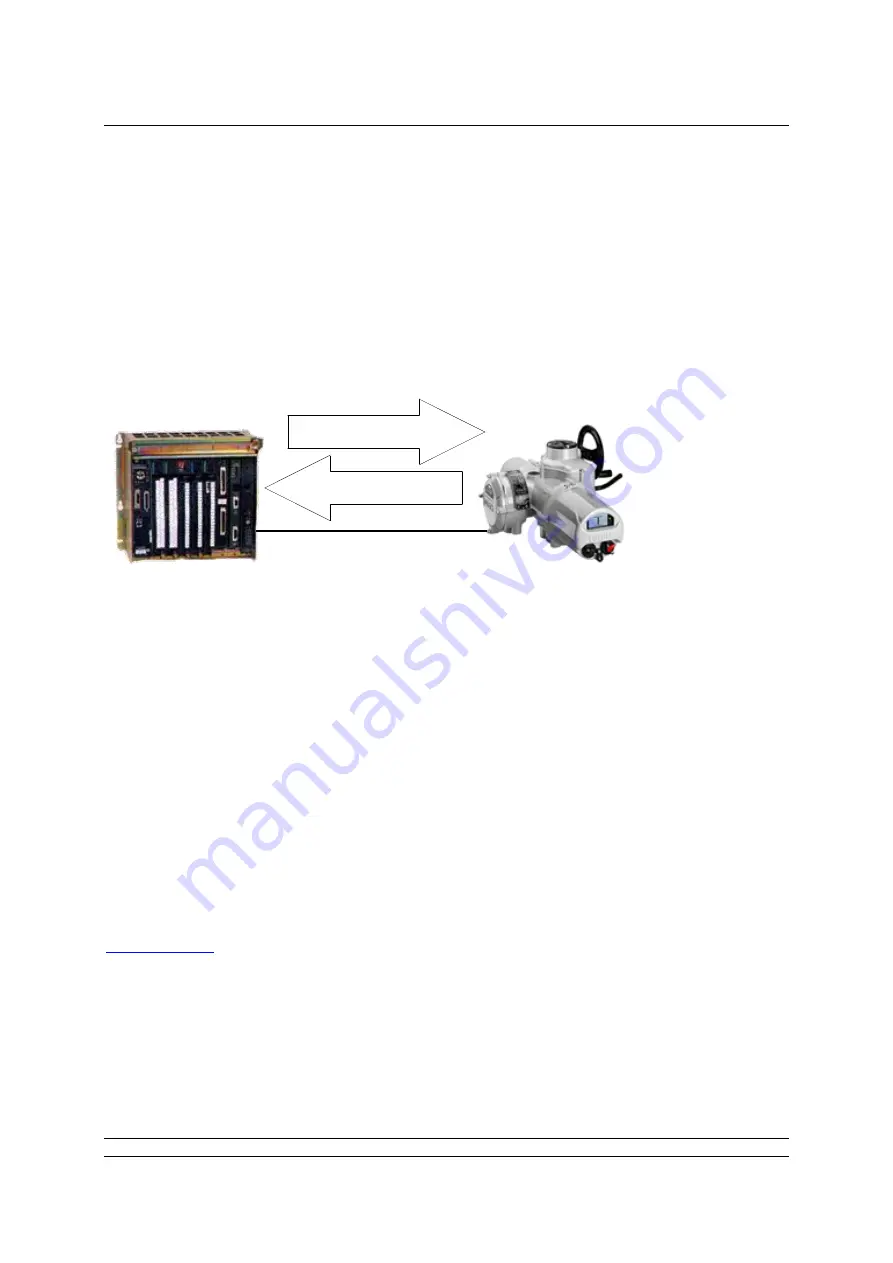

RS-485 data highway

Inputs - Feedback

Outputs - Commands

PLC

Actuator

Fig 15:

Input and Output Data Direction

Inputs

are defined as signals originating at the actuator and fed back to the PLC over the

RS-485 network, i.e. Inputs to the PLC.

Outputs

are defined as signals originating at the PLC and operating the actuator

controls, i.e. Outputs from the PLC.

5.1 Control Outputs

The MFU can be used to control the actuator to position the valve. The valve may be moved fully

closed, fully open or to an intermediate position. Additionally, the actuator can make the valve adopt

an Emergency Shut Down position or perform a partial stroke test. The actuator may also be operated

from its local controls, by hard wired direct contact inputs, or by the handwheel, where fitted. In the

case of hard wired control, the Auxiliary Input Mask and control source must be correctly set.

A description of the Auxiliary Input Mask and how to set it correctly is given in the IQ3 full

configuration, status and monitoring user manual, PUB002-040, available on the Rotork web site,

See also Section 8.1.5 for a similar explanation.

As well as controlling the actuator, the MFU can also be used to operate 4 discrete output relays when

the Digital Input / Output card also fitted within the actuator.