4

x

Commissioning and decommissioning

27

FA ROTEX Solaris RPS3 25M - 03/2010

7.

Repeat visual leakage check in accordance with work step 4.

8.

Switch off the Solaris R3 control unit.

9.

Check the filling levels in the Solaris hot water storage tanks.

10.

Set the filling time.

• Switch the Solaris R3 control unit on again (initialising phase starts).

• When the initialising phase is finished (temperature display), you can start the manual operating mode by simultaneously

pressing both arrow keys.

• Note the time it takes for the Solaris system to be filled completely. The installation is completely filled when no sound

of escaping air can be heard, and a stable flow rate is indicated (use the arrow keys to select the measuring point "Flow

rate").

• Set the determined filling time plus 20 seconds as parameter "Time P2" (see Section 5.3.6).

11.

Switch the Solaris R3 control unit back to automatic operation either by simultaneously pressing both arrow keys or by

switching the unit off/on.

The Solaris system is now ready for operation.

12.

Install heat insulation at the connection points of the pipelines.

13.

Instruct the user, fill out the acceptance report, and send it to the address indicated on the rear cover of this manual.

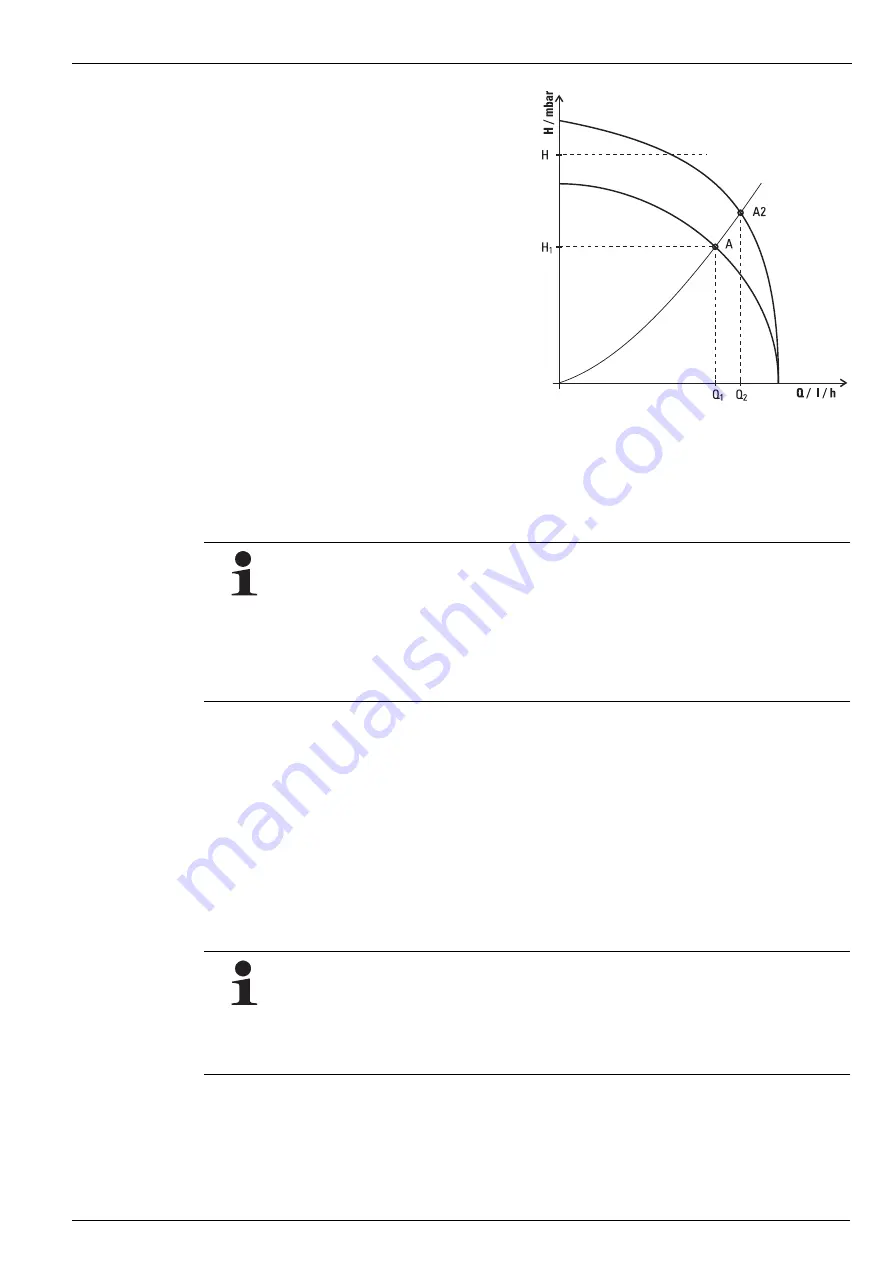

• On systems with a booster pump, it must be taken into

account that the work step after switch-off of the

booster pump will be moved. The FlowGuard valves

must therefore be set to work step "A

2

" (increased

flow rate"Q

2

").

When the FlowGuard valves have been set, the Sola-

ris system is subject to the maximum possible oper-

ating pressure.

A

Work step

A

2

Work step with connected booster pump

H

Pressure boost through the pump

H

1

Delivery capacity of the pump in work step "A"

Q

Flow rate in collector circuit

Q

1

Nominal flow rate

Q

1

Flow rate in the collector circuit in work step "A

2

"

Illustration 4-1Diagram of total pressure drop and pump delivery

capacity

The filling level indicators in the Solaris hot water storage tanks should reach roughly the fill level again within

a few minutes.

– The cause of a slightly lower fill level is the presence of a small amount of water in the lower header tubes

of the collectors. If the collector array is correctly oriented, this quantity of water presents no risk to the

collector, even with the effects of frost, as there is sufficient volume for expansion available.

– If the fill level remains significantly below the filling mark, this can be an indication of undetected leaks,

insufficient hydraulic balancing or an incorrect pipe run (waterpockets). In this case the installation must

be checked very closely once more.

The circulation pump and, where installed, the booster pump, are only switched on if the collector temperature

is above the minimum value (coupled with the frost protection temperature, see chapter 5.2.9) and lower than

the set maximum permissible temperature.

If there has been a long interval between switching off and on in Step 11, the collector temperature might be

outside the permissible range. However the system can be started manually by switching on the manual mode

for a few minutes (see Chapter 5.2.5).