24

FA ROTEX Solaris DrainBack - 09/2016

4

x

Installation

4.6

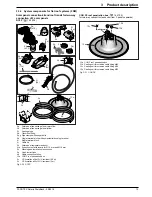

Installing the equipotential bonding terminal

1. Loosen the slotted screws on the installed equipotential bond-

ing terminal and connect the equipotential bonding cable (not

included in the scope of delivery) to the terminal. Then retight-

en the screws.

2. Lay the equipotential bonding cable up to the equipotential

bonding rail (building side) and connect it there.

Fix the equipotential bonding cable in place to the inflow pipe

or return flow pipe with cable ties.

4.7

Installing the solar panel temperature

sensor

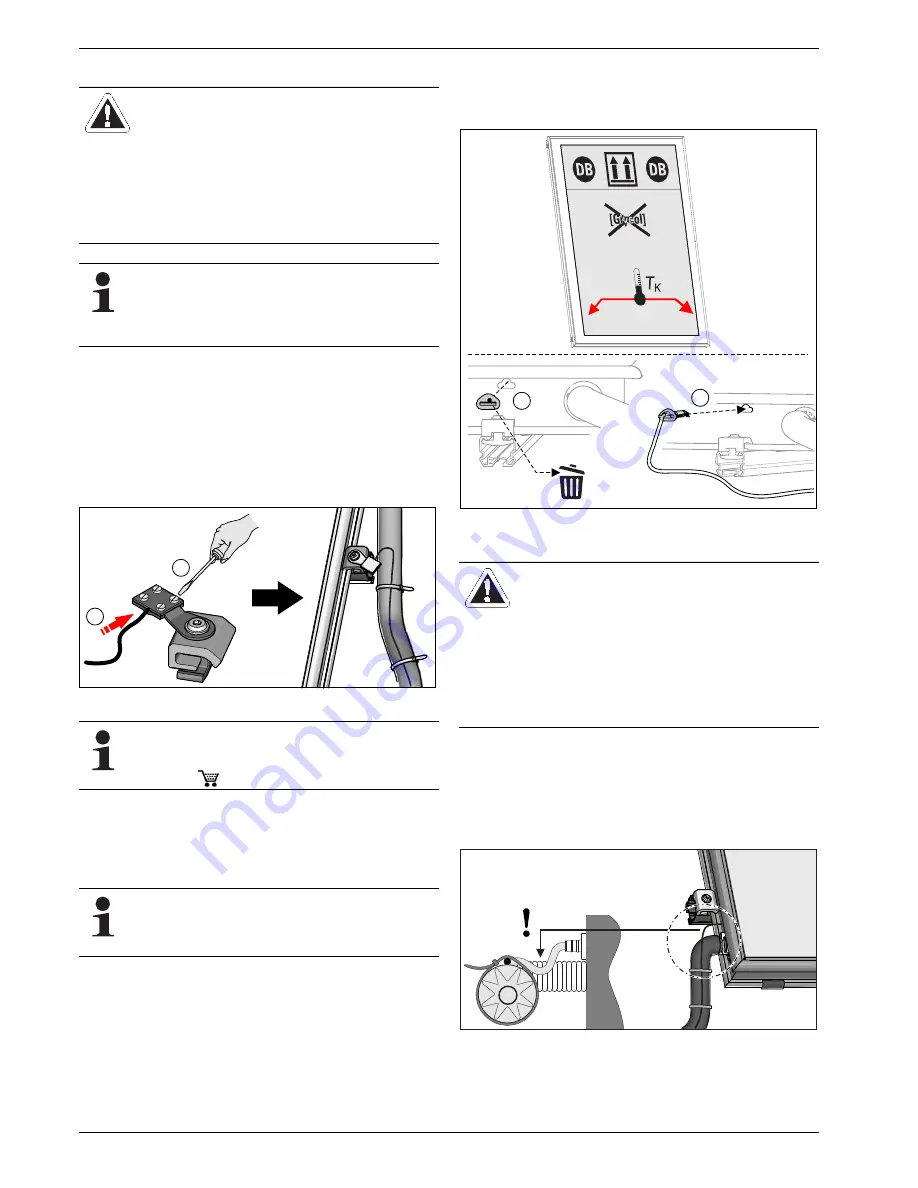

1. Remove the sensor plugs on the return flow connection side

(see fig. 4-10 and fig. 4-11, pos. a) at the bottom edge of the

solar panel.

2. Slide the solar panel temperature sensor into the installation

opening of the flat solar panel up to the end stop.

The sensor of the probe must be clamped to the absorber

plate.

3. Run the silicone-covered cable of the solar panel temperature

sensor with drip-off elbow to the roof penetration, and secure

to the mounting rail or connecting pipe using cable ties.

Then connect the silicone-covered cable inside the roof to the

connection cable of the solar panel temperature sensor of the

control and pump units.

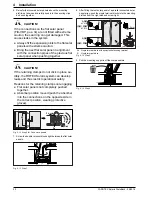

WARNING!

The equipotential bonding does not replace a

lightning conductor. It is only provided for pro-

tecting the solar panel temperature sensor and

the control unit. Local lightning strike regulations

must also be observed.

With the roof-mounted system (ADM), the equipotential

bonding terminal is attached close to the inflow con-

nection (top), with the in-roof system (IDM) and flat roof

system (FDM), in contrast, close to the return flow con-

nection (bottom).

Fig. 4-22 Steps 1+2

If two or more panel rows are installed, they must be

connected by means of an equipotential bonding. Equi-

potential bonding terminals are included in the

CON RVP (

16 20 35

) kit.

The installation openings for the solar panel temper-

ature sensor are located at the left and right of the side

solar panel frame and closed with plugs when de-

livered.

1.

2.

T

K

Solaris panel temperature sensor

Fig. 4-23 Steps 1+2

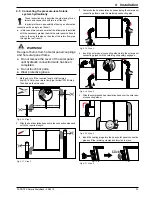

CAUTION!

Moisture can damage the temperature sensor.

●

When securing the cable, make sure that no

rainwater can run down the cable to the

sensor well (installing with drip-off elbow see

fig. 4-21).

Fig. 4-24 Step 3

2.

1.

T

K