Содержание 2005 717 RFI

Страница 1: ...C M Y CM MY CY CMY K www SeaDooManuals net...

Страница 2: ...2005 Engine Shop Manual ROTAX 717 and 787 RFI ENGINES www SeaDooManuals net...

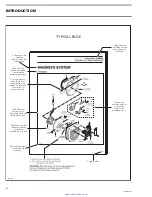

Страница 60: ...Section 02 717 ENGINE Subsection 05 ROTARY VALVE F01D73W 159 54 smr2005 079 www SeaDooManuals net...

Страница 117: ...C M Y CM MY CY CMY K www SeaDooManuals net...