Rockwell Automation Publication VIEW-IN001C-EN-P - April 2018

5

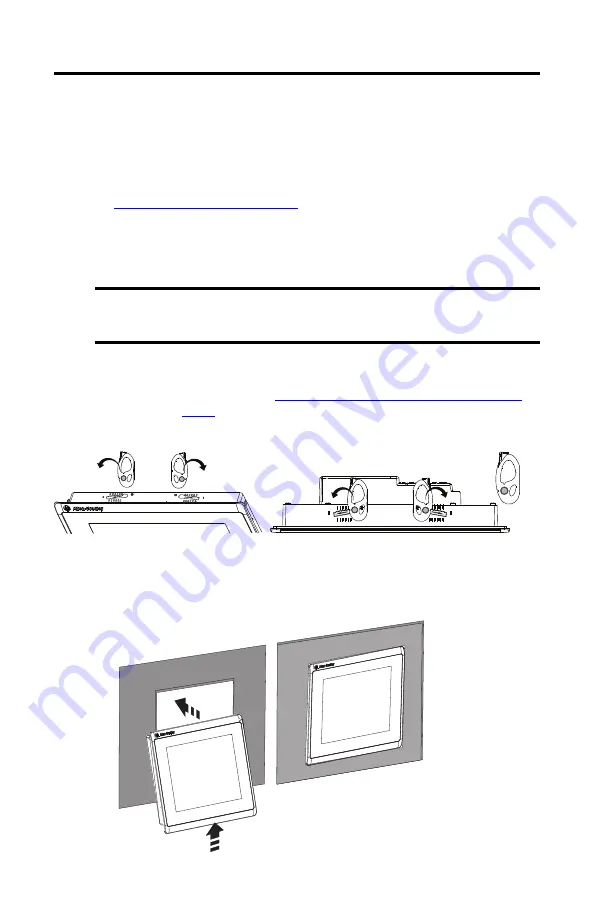

PanelView Mounting Levers

Mount the Terminal in a Panel

Follow these steps to mount your PanelView terminal in a panel cutout.

1. Use the cutout template that is shipped with your terminal to mark the cutout

dimensions and cut the hole in the panel.

Panel Cutout Dimensions on page 8

if you do not have the cutout template.

2. Verify that the sealing gasket is present on the terminal.

This gasket forms a compression type seal. Do not use sealing compounds.

3. Insert and stabilize the PanelView terminal in the panel cutout.

a. Depending on your terminal model, insert the mounting levers in the top corner

slots by using the orientation in

Mounting Lever Orientation and Lock Sequence

.

b. Rotate the round side of the mounting levers toward the panel.

c. Tilt the terminal toward the panel cutout and guide the terminal upward into the

cutout; make sure that the mounting levers stay intact.

IMPORTANT

Catalog number 2711P-RMCP mounting levers are used only with PanelView 5310,

PanelView 5500, PanelView 5510, and PanelView Plus 7 Performance terminals

(1)

.

Do not use these mounting levers with other PanelView terminals.

(1)

These mounting levers do not work on PanelView Plus 7 Performance stainless steel terminals.

TIP

The mounting levers in the top corner slots help to stabilize the terminal in the

panel while you install the remaining mounting levers.

Flat

Side

Round

Side

10.4-in. terminal shown in this example.