Features and technical data

Installation, use and maintenance manual – TS 2000

7

1

1

FEATURES AND TECHNICAL DATA

1.1

FEATURES

1.1.1

Operation

The TS 2000 gas-fired convector is an independent heat-

ing appliance with sealed combustion chamber and natu-

ral draught with balanced flow.

It has been designed to be installed inside the room to be

heated.

It can operate either with natural gas (G20) and LPG (G30/

G31) (gas-fired convector belonging to category II

2H3+

ac-

cording to EN 613).

The combustion air intake and the flue gas outlet take

place outside the installation room by means of two coax-

ial pipes. Therefore the appliance must be positioned on

an external perimeter wall.

The dual function of air intake and flue gas exhaust per-

formed by the coaxial duct does not allow for connection

to traditional flues.

The operation principle of the TS 2000 gas-fired convec-

tor is based on a convective motion of room air that pass-

es through the gas-fired convector from bottom to top,

is heated and diffused into the room through the upper

grille.

For this reason it is important not to obstruct

the air outlet by placingclothing or any other

objects over the outlet grille; always keep cur-

tains, chairs or any other furniture at least 30

cm away from the heater.

The operation of the appliance, which is very simple in

itself, is made completely automatic by the thermostatic

regulation: in fact, the user only requires the preliminary

ignition operation and the choice of the desired tempera-

ture (set on the thermostatic control knob).

The sealed combustion chamber is the best guarantee of

safety for the environment in which the gas-fired convec-

tor is installed: there is no possibility of the products of

combustion leak, nor is the oxygen necessary for combus-

tion taken from the environment. The appliance, once in-

stalled in accordance with the installation standards, does

not require any ventilation openings in the room.

A flame detection device using a thermocouple interrupts

the gas supply in the event of an accidental shutdown.

1.1.2

Mechanical components

▶

Sealed combustion chamber.

▶

High-efficiency aluminium alloy heat exchanger.

▶

Ø 100/60 mm coaxial combustion air intake and flue

gas exhaust pipes.

▶

External flue gas terminal in aluminium alloy.

▶

Casing in epoxy powder-coated sheet metal.

▶

Support bracket for wall mounting.

1.1.3

Control and safety devices

▶

Gas valve providing the following functions:

burner ignition

flame monitoring

heat exchanger temperature probe control

▶

Heat exchanger temperature control probe

▶

Piezoelectric ignition button

▶

Thermostatic control knob

1.2

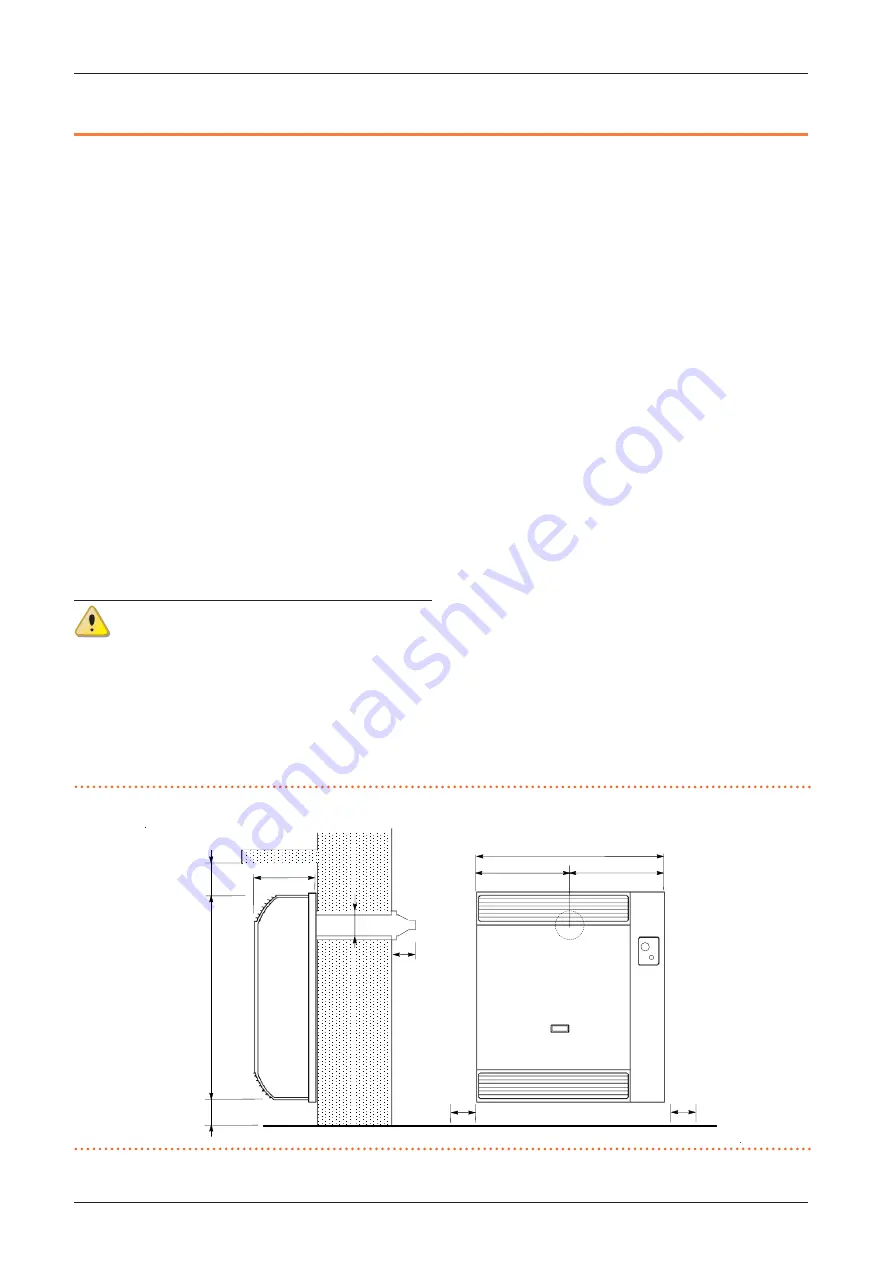

DIMENSIONS

Figure 1.1

Dimensions

170

100

480

190

290

100

1

00

< 3

50

>

50

100

100

577