SECTION 12: S

ERVICING

37

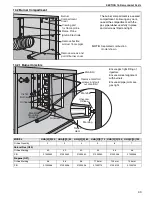

Combustion Air Intake

Pipe

Intake pipe and inlet must be intact. Look for obstructions, cracks on the pipe,

gaps in the sealed areas or corrosion.

The area must be free of dirt and dust.

Clean and reinstall as required.

Heat Exchanger

Make sure there are no cracks.

Make sure there is no sagging, bending or distortion.

Clean or replace as required.

See Page 22, Section 8

.

Gas Line and Shut-off

Valves

Check for gas leaks.

See Page 22, Section 8

.

Burner Observation

Window

Make sure it is clean and free of cracks or holes.

Clean and replace as required.

Flue Blower Scroll, Wheel

and Motor

Compressed air or a vacuum cleaner may be used to clean dust and dirt.

Inshot Burners and

Orifices

Clear obstructions (even spider webs will cause problems).

Carefully remove any dust and debris from the burner.

Direct-Spark Igniter

Replace if there are cracked ceramics, excessive carbon residue, or erosion

of the electrode.

The electrode gap should be 1/8" (3.2 mm).

Thermostat

There should be no exposed wire or damage to the device or wiring.

See Page 29, Section 10

.

Suspension Points

Make sure the heater is hanging securely.

Look for signs of wear on the suspension materials or ceiling.

See Page 11, Figure 5

.

Silicone Tubing

Ensure tight, secure fit on all pressure fittings at pressure switch,

burner partition, and blower outlet.

Gas Valve

Verify that cap covering pressure regulator adjustment screw is secure and

has not been tampered with.

Verify all wiring connections.

Condensate Drain

(when installed)

Flush drain and clear any obstructions.

Wall Tag

If wall tag is present, make sure it is legible and accurate. Please contact

Roberts Gordon LLC or ROBERTS GORDON® independent distributor if you

need a wall tag.

See Page 5, Section 2.1

.