Rhein-Nadel Automation GmbH

9

VT-BA-ESR2000_EN-2019 / 05.08.2019 SJ

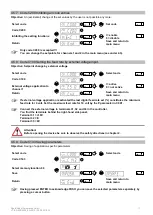

10. Select code 001 again as described above.

Select code

KANAL l

KANAL 2

CODE

Set code

Code C001

KANAL l

KANAL 2

CODE

11. Increase amplitude to 90 %:

Set vibrating amplitude

KANAL l

KANAL 2

CODE

0 - 100 %

12. Reduce the vibrating frequency until the required feed rate is obtained.

Vibratory drive operating frequency

KANAL l

KANAL 2

CODE

45 - 120

13. Check the load current; it must not exceed the maximum value!

The RNA - plug-in adapter ESZ-01 greatly facilitates start-up and, in particular, determination of the load

current.

14. Save the operating parameters chosen

Return

KANAL l

KANAL 2

CODE

Save and return to

main menu

If you are not sure whether the controller is in the factory default setting, select menu C210 "Retrieve parameters" as

described under 4.5.10 to call up the default setting.

Attention

:

In case of bumping of the bowl feeder during commissioning (very loud metallic noise):

Stop the controller immediately!

Commissioning without observing the above measures creates the risk of destroying the feeder or parts

thereof. This would void any warranty!

After successful commissioning you can activate the sensor amplifier and set the delay periods and soft start/stop

times, if required.

3.6.

Sensor inputs and sensor linkages

The controller has two sensor inputs which are used for accumulation checking, level checking, cycle monitoring and

other monitoring functions. The following basic assignments are made:

Sensor input 1 acts on channel 1, unless otherwise programmed in menu C006. Sensor input 2 is provided for

additional functions, see sensor linkage. The sensor inputs can be evaluated only if they are activated in codes C004

and C005. The connection diagram is shown in the sensor plug connector (XS3).