Rhein-Nadel Automation GmbH

15

VT-BA-ESR2000_EN-2019 / 05.08.2019 SJ

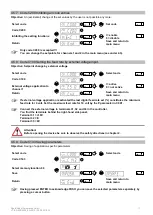

4.5.4. Code C006 Sensor linkage

Objective:

Linking of the two previously activated sensor inputs.

Select code

KANAL l

KANAL 2

CODE

Set code

Code C006

KANAL l

KANAL 2

CODE

You can activate only one of the eight sensor links.

AND logic with blowing-off

the exit tracks

KANAL l

KANAL 2

CODE

I = active

0 = not active

AND logic without blowing-off the exit

tracks

(from version No. 10

)

KANAL l

KANAL 2

CODE

I = active

0 = not active

OR logic

KANAL l

KANAL 2

CODE

I = active

0 = not active

Min/Max logic

KANAL l

KANAL 2

CODE

I = active

0 = not active

AND / S2 logic

(from version No. 10

)

KANAL l

KANAL 2

CODE

I = active

0 = not active

Level check for hopper control

(From version No. 10

)

KANAL l

KANAL 2

CODE

I = active

0 = not active

Level check indicator light

KANAL l

KANAL 2

CODE

I = active

0 = not active

Individual link

KANAL l

KANAL 2

CODE

I = active

0 = not active

Return

KANAL l

KANAL 2

CODE

Save and return to

main menu

Brief description of individual links

AND logic of the two sensor inputs with blowing-off the exit tracks.

Example:

Application:

Twin-track feeders with accumulation checker.

Solution:

Track 1 (sensor 1) full = Blow-off track 1 (relay K1)

Track 2 still clear

Track 2 (sensor 2) full = Blow-off track 2 (relay K2)

Track 1 still clear

Track 1 + Track 2 full = Bowl feeder (channel 1) Stop about 4 sec. later blowing air

stop

AND logic of the two sensor inputs without blowing-off the exit track.

Bowl feeder (channel 1) stops when both sensors are operated. Orienting air can be switched off with

delay (4 sec.) via relay K2.

OR logic of the two sensor inputs.

Bowl feeder (channel 1) stops when one of the two sensors is operated. Orienting air can be switched

off with delay (4 sec.) via relay K2.

Min/Max logic of the two sensor inputs.

The bowl feeder stops when both sensors are operated. The bowl feeder (channel 1) will re-start only

after both sensors are cleared again.

Relay K1 operates on stopping of bowl feeder. Relay K2 operates 4 sec. later (stopping the blowing air)

AND / S2 logic

Bowl feeder (channel 1) stops when both sensors are operated. It starts when sensor 2 is cleared

again. Orienting air can be switched off with delay (4 sec.) via relay K2.

Level check for hopper control

Sensor 2 operates relay K1 following the delay period entered (C005).

When sensor 1 is operated, relay K1 drops out. (Hopper interlock)

Application:

Sensor 1 = accumulation check;

Sensor 2 = level check;

Relay K1 = hopper control

Level check with indicator light

Sensor 2 operates relay K1 following the delay period entered (C005).