41

2.7 CIRCULATION PUMP

The boiler is supplied, as standard, with a built-in circulator with high energy efficiency, already compliant with

Regulation 641/2009/EU.

The pump is directly managed by the PCB of the boiler and has an automatic operation: it is set for the most suitable

operation based on the measured temperature difference between flow and return.

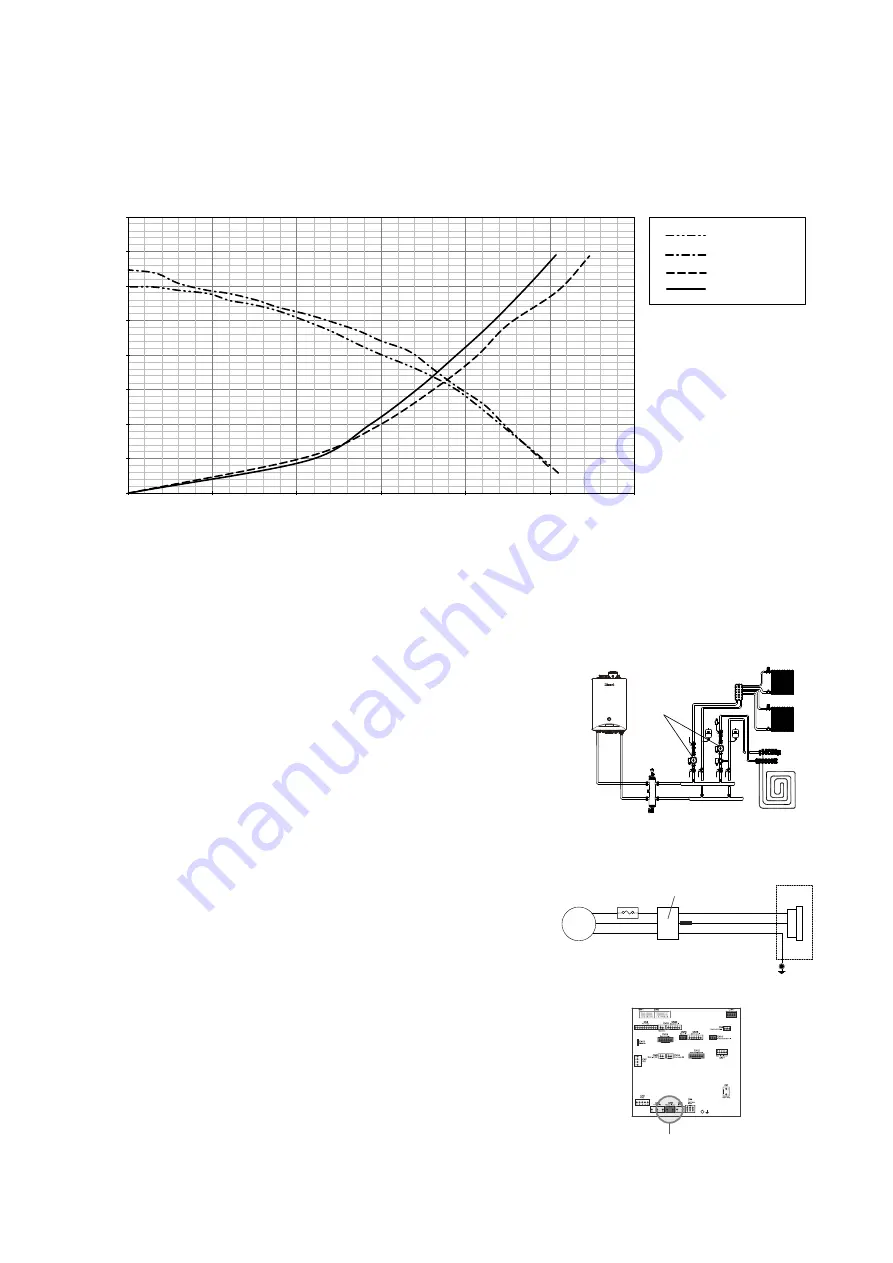

In the lower diagram are shown the specific curve of the pump and the losses of the heat exchanger:

Secondary circulating pump

In specific applications, due to the high losses in the system, the free head

of the circulation pump may be poor or insufficient for the correct circulation

of water in the heating circuit. For this purpose an optional accessory is

available to connect a secondary pump external to the boiler. The operation

of the secondary pump is managed, quite simply, like the operation of

the primary pump: the pump is activated during the heating phases,

when antifreeze protection is required, and when the initial functional test

(deaeration cycle) is performed.

The characteristics of a compatible supplementary pump are:

Voltage: 230V AC, 50Hz

Amperage: <1 A

Inrush current: <1.5 A

(pumps with special and different technical charachteristics may cause the

improper functioning of the boiler and damage the PCB).

Installation:

•

unplug the boiler;

•

install the pump into the CH system;

•

connect the pump wire to the blue CN5 connector on the PCB;

•

remove the connector from the free end of the wire and join it to the

pump following the electrical scheme on the right side;

•

the installation of a 3Amp fuse is recommended.

0

100

200

300

400

500

600

700

800

0

200

400

600

800

1000

1200

Head

[m

ba

r]

Flow rate [ l/ h]

Head Z34

Head Z25/Z29

Losses Z34

Losses Z25/Z29

CN5 (blue) port

Main electric board

Electrical connection of the secondary pump

Secondary

pump

(L)

3A fuse

(N)

(Ground)

Blue (L)

PCB

CN5

Cut the connector

and join the wires

Black (N)

Yellow/Green(Ground)

Secondary

pump*

System connection

* = it is possible to connect only one secondary pump