2. Upon completion of parameter initialization, the machine returns to the initial stage of the maintenance

mode.

3. Be sure to turn the machine power off. If you press the "9" key twice to exit from the maintenance

mode without turning the power off, then the machine will not fully initialize the EEPROM.

Printout of Scanning Compensation Data (Function code 05)

Function

The machine prints out the white and black level data for scanning compensation.

Operating Procedure

Do not start this function merely after powering on the equipment but start it after carrying out a sequence

of scanning operation. Unless the equipment has carried out any scanning operation, this function cannot

print out correct scanning compensation data. This is because at the start of scanning operation, the

equipment initializes white and black level data and takes in the scanning compensation reference data.

1. Press the "0" and "5" keys in this order in the initial stage of the maintenance mode.

The "WHITE LEVEL 1" will appear on the LCD.

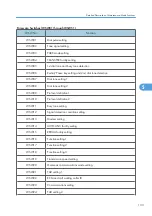

2. The equipment prints out the scanning compensation data list containing the following:

a) Bright output adjustment value 1Byte

b) Illuminant adjustment value 1Byte

c) Black level MIN data 1Byte

d) Black level MAX data 1Byte

e) White level MIN data 1Byte

f) White level MAX data 1Byte

g) Background color compensated data 1Byte

h) Black level data 1664Byte

i) White level data 1664Byte

3. Upon completion of recording of the compensation data list, the equipment returns to the initial stage

of the maintenance mode.

• If any data is abnormal, its code will be printed in inline style, as shown on the next page.

5. Service Maintenance

130

5

Содержание HL-F1

Страница 1: ...Model HL F1 Machine Code H558 Field Service Manual 14 May 2010...

Страница 2: ......

Страница 13: ...1 Product Information Specifications See Appendices for the Specifications 11 1...

Страница 15: ...Rear View 12 USB Interface Connector 13 Back Cover 14 AC Power Connector Overview 13 1...

Страница 18: ...Components The equipment consists of the following major components 1 Product Information 16 1...

Страница 22: ...2 Installation 20 2...

Страница 23: ...3 Preventive Maintenance PM Tables There are no PM parts for this machine 21 3...

Страница 24: ...3 Preventive Maintenance 22 3...

Страница 33: ...Disassembly Flowchart Before You Do 31 4...

Страница 34: ...Common Parts Paper Eject Tray 1 Remove the paper eject tray A Drum Toner ASSY 4 Replacement and Adjustment 32 4...

Страница 43: ...4 Remove the separation rubber A ADF plate spring B and front plate spring C x 1 B M3x6 Common Parts 41 4...

Страница 44: ...5 Remove the actuator R A from the panel unit B 4 Replacement and Adjustment 42 4...

Страница 45: ...6 Release the four hooks to remove the panel rear cover A x 3 B M3x8 Common Parts 43 4...

Страница 48: ...11 Remove the rubber key A 4 Replacement and Adjustment 46 4...

Страница 51: ...Top Cover 1 Rear Chute Cover p 34 2 Remove the rear cover stopper A x 1 B M4x12 Common Parts 49 4...

Страница 60: ...22 Remove the CIS A 23 Disconnect the CIS harness A 4 Replacement and Adjustment 58 4...

Страница 61: ...24 Remove the two CIS springs A 25 Remove the LF roller gear A Common Parts 59 4...

Страница 63: ...28 Remove the scanning motor F sub ASSY A x 1 M3x6 Common Parts 61 4...

Страница 101: ...4 Remove the HVPS insulation sheet A 5 Remove the gear plate calking ASSY B x 3 B M4x12 Main Body 99 4...

Страница 106: ...2 Remove the main frame L A x 2 B M4x12 Main Frame R 1 Main Frame L p 103 4 Replacement and Adjustment 104 4...

Страница 107: ...2 Remove the main frame R A x 3 B M4x12 Main Body 105 4...

Страница 110: ...FG harness ASSY 1 Main PCB 2 FG harness ASSY 3 Laser unit 4 Replacement and Adjustment 108 4...

Страница 111: ...Regist sensor PCB ASSY 1 PS PCB unit 2 Regist sensor PCB ASSY 3 Chute Harness Routing 109 4...

Страница 112: ...Fan Motor 60 Unit 1 Fan motor 60 unit 2 Main PCB 4 Replacement and Adjustment 110 4...

Страница 113: ...Toner LED PCB ASSY Fan 40 1 Fan 40 2 Label side 3 Toner LED PCB ASSY 4 PS PCB unit Harness Routing 111 4...

Страница 114: ...Toner Sensor PCB ASSY 1 High voltage PS PCB ASSY 2 Toner sensor PCB ASSY 4 Replacement and Adjustment 112 4...

Страница 120: ...CIS 1 Main PCB 2 CIS 4 Replacement and Adjustment 118 4...

Страница 153: ...7 Select Search for a suitable driver for my device recommended and click Next Firmware Installation 151 5...

Страница 155: ...10 Click Next Firmware Installation 153 5...

Страница 156: ...11 To proceed click Yes 5 Service Maintenance 154 5...

Страница 218: ...Image Defects 6 Troubleshooting 216 6...

Страница 255: ...Model HL F1 Machine Code H558 Appendices 14 May 2010...

Страница 256: ......

Страница 258: ...2...

Страница 296: ...2 Appendix Troubleshooting Guide 40 2...