Installation, Disassembly, and Adjustments

• After installation, maintenance, or adjustment, always check the operation of the machine to make

sure that it is operating normally. This ensures that all shipping materials, protective materials, wires

and tags, metal brackets, etc., removed for installation, have been removed and that no tools

remain inside the machine. This also ensures that all release interlock switches have been restored

to normal operation.

• Never use your fingers to check moving parts causing spurious noise. Never use your fingers to

lubricate moving parts while the machine is operating.

Special Tools

• Use only standard tools approved for machine maintenance.

• For special adjustments, use only the special tools and lubricants described in the service manual.

Using tools incorrectly, or using tools that could damage parts, could damage the machine or

cause injuries.

During Maintenance

General

• Before you begin a maintenance procedure: 1) Switch the machine off, 2) Disconnect the power

plug from the power source, 3) Allow the machine to cool for at least 10 minutes.

• Avoid touching the components inside the machine that are labeled as hot surfaces.

Safety Devices

• Never remove any safety device unless it requires replacement. Always replace safety devices

immediately.

• Never do any procedure that defeats the function of any safety device. Modification or removal of

a safety device (fuse, switch, etc.) could lead to a fire and personal injury. Always test the

operation of the machine to ensure that it is operating normally and safely after removal and

replacement of any safety device.

4

Содержание CS4010

Страница 1: ...Mail Box CS4010 Machine Code D708 Field Service Manual May 2016 ...

Страница 2: ......

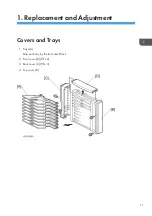

Страница 16: ...3 Control board x2 x15 1 Replacement and Adjustment 14 ...

Страница 19: ...Drive Layout No Part 1 Drive Belt 2 Driven Belt 3 Transport Motor Overview 17 ...

Страница 28: ...MEMO 26 ...

Страница 29: ...MEMO 27 ...

Страница 30: ...MEMO 28 EN ...