Form I-XE/CRGB/RPB, Page 42

Top Baffle

Support

Screws B

Bottom

Baffle Support

Brackets

Air

Discharge

Dir

ection of

Airflow

Screw C

Right

Left

Screws A

Scr

ew C

Flue Diverter

(Sizes 225-400 only)

Tube Baffle

Collection Box End

Blockoff Plate

Screw

Collection

Box End

Screw

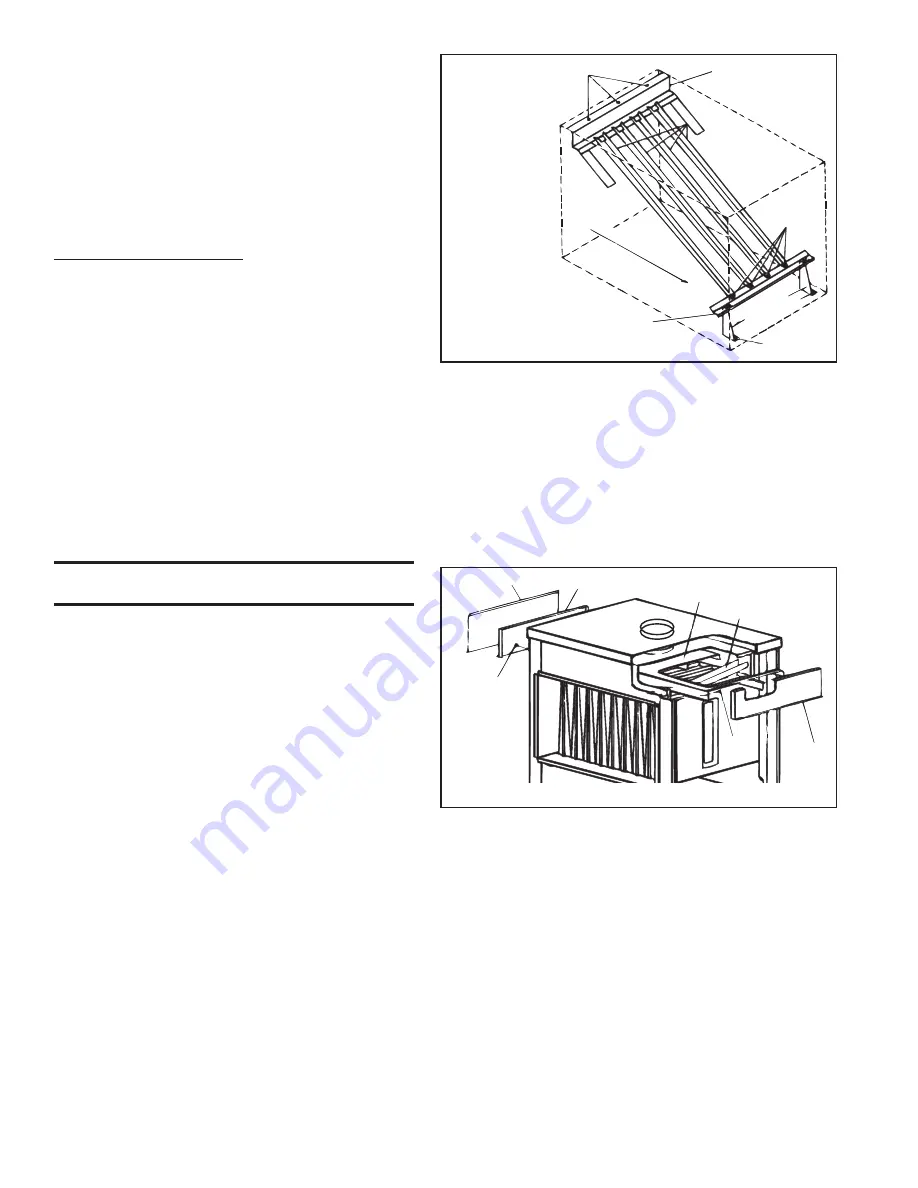

FIGURE 48 -

When cleaning

outer heat

exchanger

surface, remove

directional

air baffles.

Remove Screws

"A" and slide

baffles out.

Clean and

replace all

baffles.

NOTE: High

CFM furnaces

do not have

directional air

baffles.

38. Burner Rack Removal

Instructions

1.

Turn off the gas supply.

2.

Turn off the electric supply.

3.

Remove control access side panel.

4.

Disconnect the pilot tubing and flame sensor lead (spark pilot).

5.

Mark and disconnect electric valve leads.

6.

Uncouple the union in the gas supply.

7.

Remove sheetmetal screws in the top corners of the burner

rack assembly.

8.

Pull "drawer-type" burner rack out of the furnace.

To disassemble the burner rack:

1.

Remove Carryover System -

Natural Gas

- Remove the flash carryover system from the

"manifold end" of the burner rack.

NOTE:

Natural gas burner

racks manufactured prior to 3/95 have a lighter tube carryover

system. Break the lighter tube connection at the orifice and re-

move the supply tubing, the drip shield and the lighter tube.

Propane Gas

- Break the lighter tube connection at the regulator

and remove the lighter tube orifice supply tubing; remove the

retaining screws in the drip shield and the shield; remove the

retaining screws and slide out the lighter tube.

2.

Pull main burners horizontally away from injection opening

and lift out.

3.

Remove manifold bracket screws and remove manifold.

4.

Change main burner orifices, if necessary.

5.

Remove screws and lift out pilot burner.

Follow the instructions in Paragraph 39 to clean. To re-assemble and

replace, reverse the above procedures being careful not to create any

unsafe conditions.

CAUTION: When cleaning, wearing eye

protection is recommended.

39. Cleaning Pilot & Main Burners

In the event the pilot flame is short and/or yellow, check the pilot

orifice for blockage caused by lint or dust accumulation. Remove the

pilot orifice and clean with air pressure. DO NOT REAM THE

ORIFICE. Check and clean the aeration slot in the pilot burner.

Clean the metal sensing probe and the pilot hood with an emery

cloth and wipe off the ceramic insulator. Check the spark gap; spark

gap should be maintained to 7/64". After the pilot is cleaned, blow

any dirt away with compressed air. (See ignition requirements in

Paragraph 27.)

Clean the main burners with air pressure. Use an air nozzle to blow

out scale and dust accumulation from the burner ports. Alternately

blow through the burner ports and the venturi. Use a fine wire to

dislodge any stubborn particles. Do not use anything that might

change the port size.

Clean the burner rack carryover systems with air pressure.

40. Cleaning the Heat Exchanger

To clean the outer surfaces (circulating air side) of the heat exchanger,

gain access by removing the inspection panels in the ductwork or

remove the ductwork. Depending on whether or not the furnace is

designed for high CFM (Model prefix "H"), there may be directional

baffles between the heat exchanger tubes. The standard furnace has

baffles between the heat exchanger tubes as shown in

FIGURE 48

.

(High CFM furnaces have only the top baffle support which does

not need to be removed for cleaning.) To remove the baffles, remove

the screws marked "A" in

FIGURE 48,

and slide each baffle forward.

Use a brush and/or an air hose to remove accumulated dust and

grease deposits from the tubes and the baffles. Re-install the baffles

by sliding them into the rear slot and replacing the screw.

The inner surfaces (combustion air side) of the heat exchanger can be

reached for cleaning with the burner rack removed. (See Paragraph

38.) An air hose; an 18-24" long, 1/2" diameter furnace brush (or heavy wire

with steel wool securely attached); a flashlight; and a mirror are needed.

The required procedure depends on the date of manufacture and whether or

not the furnace is rated for high (80%) efficiency. Furnaces designed to

provide high efficiency heating have "V" shaped baffles in the top of each

heat exchanger tube. Follow these instructions to remove these baffles

when cleaning the inner surfaces of the heat exchanger.

NOTE:

High efficiency furnaces manufactured prior to 3/95 have a "C"

prefix in their model designation. All furnaces manufactured beginning 3/95

are designed for high efficiency and include these heat exchanger "V" baffles.

Instructions to Remove Heat Exchanger "V" Baffles:

Outdoor, Gravity Vent Model Series CRGB (See FIGURE 49)

1) Remove the ends of the flue gas collection box. On the control side of

the furnace, remove the block-off plate to gain access to the collection

box end.

2)

Sizes 75-175

- Remove one of the tube baffle retaining angles on each

inside wall of the collection box. Each angle has one screw.

Sizes 200-400

- Remove the flue diverter. Remove the screw at each

end and slide the flue diverter out of the furnace.

3) Pull the "V" baffles out of the heat exchanger.

Outdoor, Power Vent Model Series RPB

1) Remove the ends of the flue gas collection box. On the control side of

the furnace, remove the venter assembly and the flue outlet duct to

gain access to the collection box end.

2)

Sizes 125-300

- Remove one of the tube baffle retaining angles on

each inside wall of the collection box. Each angle has one screw.

Size 400

- Remove the inner baffle from the flue collection box. On

the control side, align the inner baffle with the slot in the collection

box edge. Pull the inner baffle until it clears the heat exchanger.

Remove the screw at each end and slide the flue diverter out of the

furnace.

3) Pull the "V" baffles out of the heat exchanger.

FIGURE 49 -

Remove

"V" Baffles to Clean Inner Surface of Heat Exchanger Tubes