Maintenance

Servitec 35-120 with Touch controller — 06.07.2016 - Rev. B

English — 69

10.2

Cleaning

10.2.1

Cleaning the dirt trap

CAUTION

Risk of injury due to pressurised liquid

If installation, removal or maintenance work is not carried out correctly, there is a risk of burns and other injuries at the connection

points, if pressurised hot water or hot steam suddenly escapes.

•

Ensure proper installation, removal or maintenance work.

•

Ensure that the system is de-pressurised before performing installation, removal or maintenance work at the connection points.

Clean the dirt trap in the make-up and overflow line.

•

After the degassing time has elapsed.

•

After the maintenance intervals have elapsed.

An inspection is also required after longer lasting operation.

Proceed as follows:

1. Switch to Stop mode.

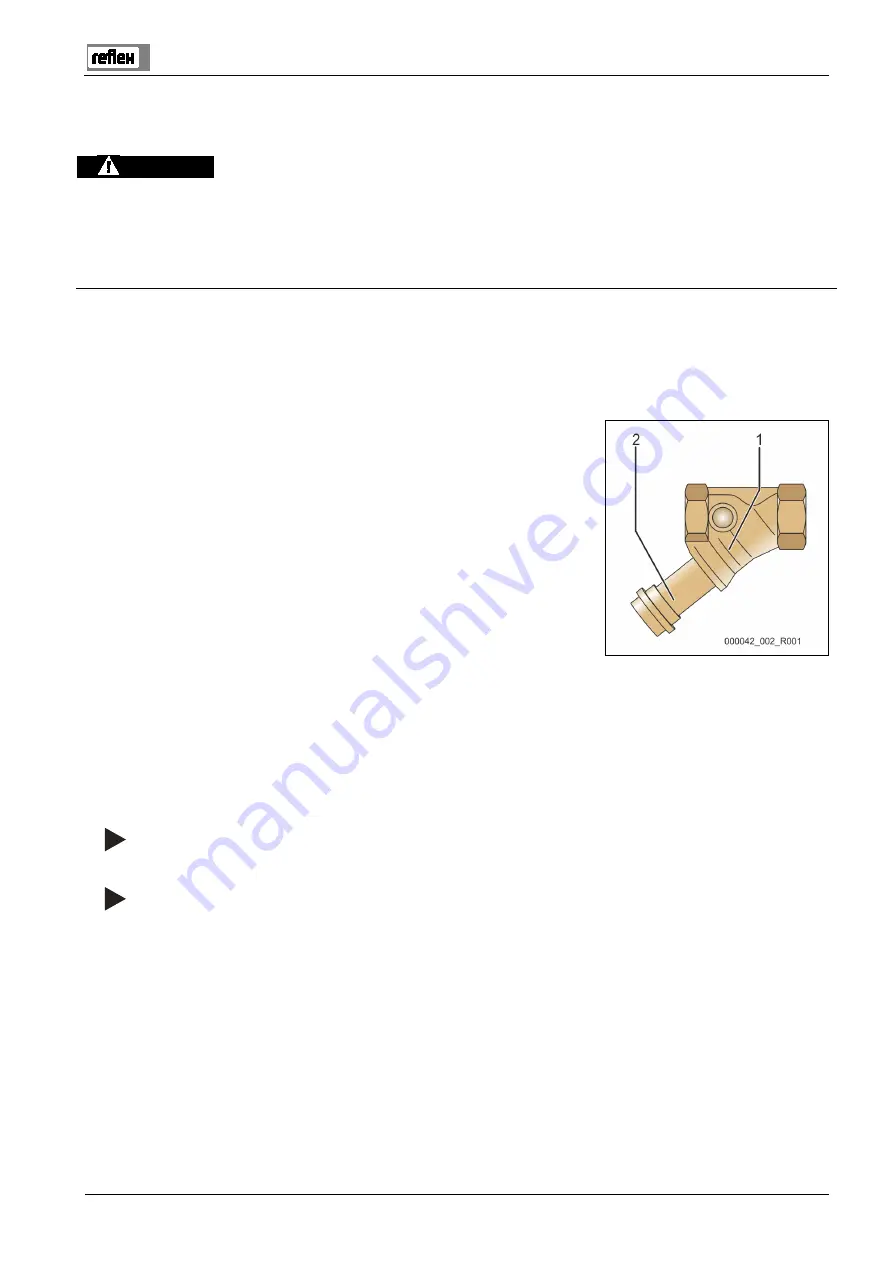

2. Close the ball valves upstream of the dirt trap (1).

3. Slowly screw the insert (2) out of the dirt trap.

– The residual pressure in the pipe section escapes from the dirt trap.

4. Remove the sieve from the insert.

5. Rinse the sieve with clean water.

6. Use a soft brush to clean the sieve.

7. Push the sieve onto the insert.

8. Check the insert seal for damage

– If necessary replace the seal.

9. Screw the insert into the housing of the dirt trap (1).

10. Open the ball valves upstream of the dirt trap (1).

11. Vent the "PU“ pump, see chapter 7.4 "Filling the device with water and venting" on

page 39 .

12. Switch to Automatic mode.

The dirt trap has been cleaned.

Note!

Clean all other installed dirt traps (in the Fillset, for example).

Note!

Perform a fine adjustment of the hydraulic compensator, if the dirt traps are heavily soiled.