42

9. Maintenance

(EX-PS only)

After every cutter has been set, check the depth

gauge and file it to the proper level as illustrated.

(MA7)

Be sure to round off the front edge to reduce

the chance of kickback or tie-strap breakage.

(1) Appropriate gauge checker

(2) Make the shoulder round

(3) Depth gauge standard

Make sure every cutter has the same length and

edge angles as illustrated. (MA8)

(4) Cutter length

(5) Filing angle

(6) Side plate angle

(7) Top plate cutting angle

■

GEAR CASE

The reduction gears are lubricated by

multipurpose, lithium-based grease in the

gearcase.

Supply new grease every 25 hours of use or more

often depending on the job condition.

When adding lubricant, use a grease gun to insert

lubricant into the three grease nipples located on

the gear case. (MA9)

(1) Grease fitting

WARNING

EX-PS

MA8

EX-PS

MA7

EX-PS

MA9

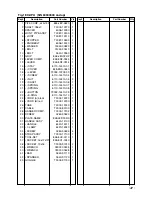

Содержание EXtreme EX-HE

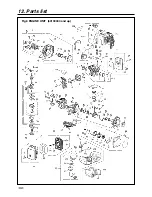

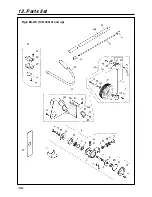

Страница 46: ...12 Parts list 46 Fig 1 EXZ PU S N 60300000 and up...

Страница 48: ...12 Parts list 48 Fig 2 EX2 BC S N 50200000 and up...

Страница 50: ...Fig 3 ENGINE UNIT 60100000 and up 50 12 Parts list...

Страница 52: ...12 Parts list 52 Fig 4 EX LRT S N 000531 and up...

Страница 54: ...12 Parts list 54 Fig 5 EX PS S N 000000 and up...

Страница 56: ...12 Parts list 56 Fig 6 EX HE S N 000101 and up...