Commissioning

ELECTRICAL INSTALLATION

WATER CIRCULATION SYSTEM

COMMISSIONING THE COOKER

AND BOILER

INSTRUCT THE USER

LIGHTING THE BOILER BURNER

BOILER OUTPUT SETTING

BOILER COMBUSTION

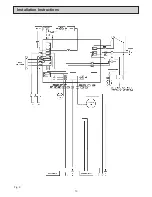

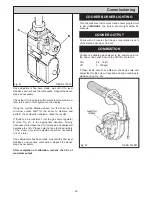

Fig. 20

DESN 514873

19

Checks to ensure electrical safety should be carried out

by a competent person i.e. earth continuity, polarity and

resistance to earth.

The whole of the system should be thoroughly flushed

out with cold water without the pump in position. Ensure

that all valves are open. With the pump fitted, the system

should be filled.

Vent all heat emissions and check for water soundness.

Insert condensate trap.

Isolate electricity supply at the wall socket. Turn the

cooker and boiler control knob to off.

After ensuring gas is available to the appliance, loosen

joint and purge any air from the supply pipe.

WARNING: NO SMOKE OR NAKED LIGHTS.

Tighten joint and check gas service cocks are in the ON

position. Check for gas soundness up to the gas valves.

1.

Advise the User of the precautions necessary to

prevent damage to the heating system and to the

building in the event of the heating system being

inoperative during frost conditions.

2.

Advise the User for continued efficient and safe

operation of the appliance. It is important that

adequate servicing is carried out at regular 12

monthly

intervals.

3.

Hand the Users Instructions to the User and

demonstrate the correct operation of the appliance

and system controls.

4.

Leave the Installation, Servicing and Users

instructions with the User.

5.

Gas Safety -

Show the user the procedure for

isolating the appliance from the gas and electric

supply. As referred to in the Users Instructions - Ref.

Gas Leak or Appliance Fault.

To light the burner - turn the boiler thermostat to maximum

and create a demand on the room thermostat.

Check the gas consumption and ensure it is ±5% of the

nominal, 26.7 kW.

Connect a suitable analyser to the flue outlet of the boiler.

(See Fig. 20).

Although the appliance is pre-set check that the CO

2

/CO

levels are within tolerances.

CO

2

8.8 - 10.2%

CO

0-50ppm

To check the levels at full rate, turn the boiler knob fully

clockwise.

To check the levels at the low rate, turn the boiler knob to

the first segment of the dial.

If these levels are within the tolerance, no further action is

required with the boiler.

If levels are not within tolerance check for possible causes

e.g. blocked flue, faulty fan etc. If non other fault can be

detected, the gas valve needs to be adjusted manually.

To do this, turn the boiler knob fully clockwise to create

the highest possible demand.

Turn the gas valve regulator A (See Fig. 21) in the

appropriate direction. Turning clockwise will decrease the

CO

2

turning anti-clockwise will increase the CO

2

. Please

note that due to the sensitivity of the screw, only small

adjustments will be necessary.

Содержание Heatranger 480CD

Страница 13: ...Installation Instructions 13 Fig 9 ...

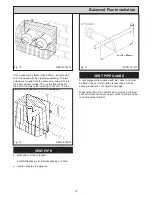

Страница 18: ...Sealed System Fig 19 18 ...

Страница 21: ...21 ...

Страница 22: ...22 ...

Страница 23: ...23 ...