RaiseTouch User Manual Date:03/03/2020

- 67 / 80 -

www.raise3d.com

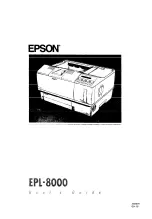

2.5 Pause and Stop

Pause Print:

pause print during printing.

Stop Print:

stop the printing.

Pause/Stop Print

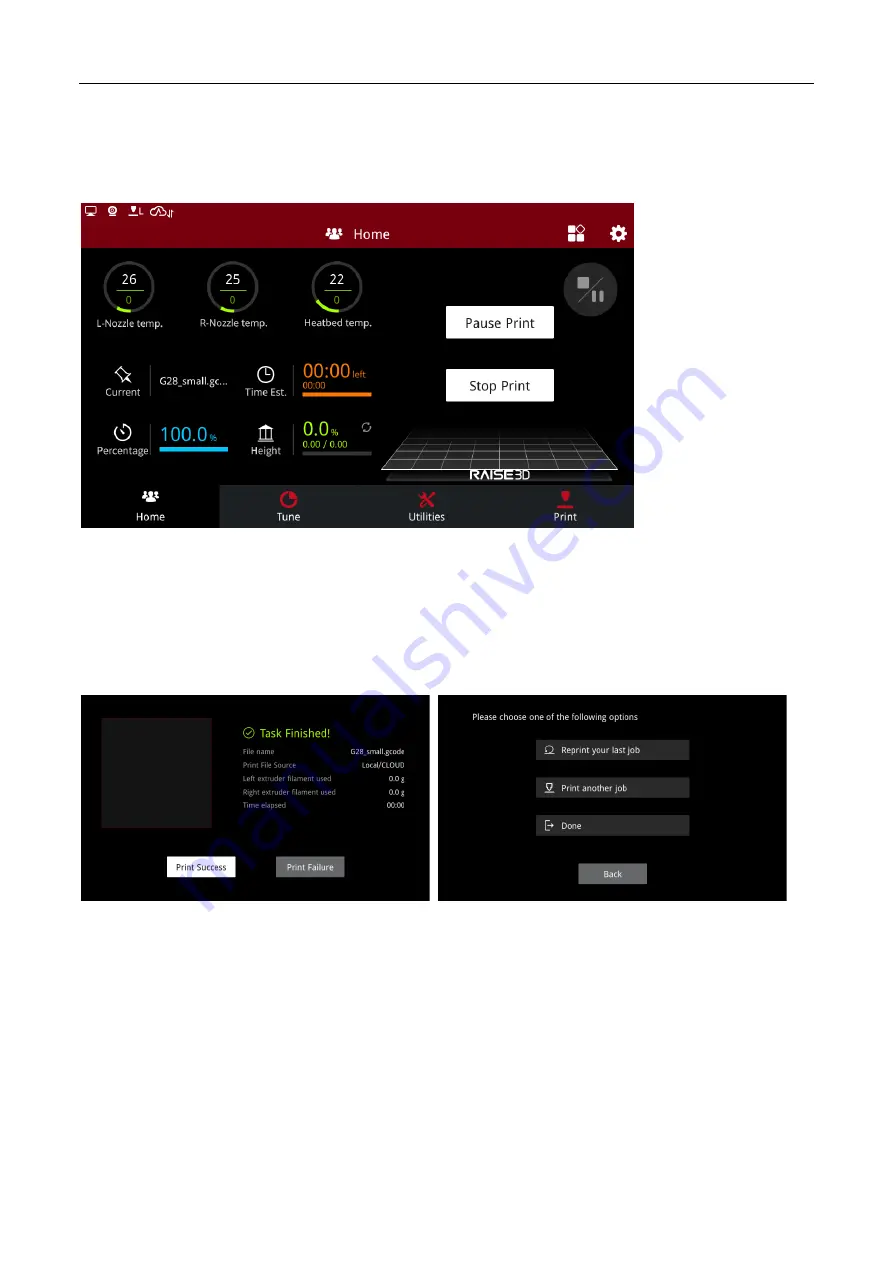

2.6 Finish the printing

Reprint:

Reprint the Model.

Print Another Job:

Jump to the file page and select a new print model.

Done:

Return to the home page.

Task Finished