8

5. Maintenance

This filter, while automatic in function, is not maintenance free. It is expected that the screen will require pressure washing on a periodic

schedule to remove contaminants that have stapled into the screen. Depending on the contaminant, the frequency can vary from once

a week to twice a year. This schedule will have to be determined based on the effectiveness of the backwash on the contaminants being

filtered. The filter must be de-pressurized to remove the screen.

5.1 Cleaning Filter Screen

The HN-G Filter Screen should be inspected every 3 months for wear and tear and be cleaned using a pressure washer directed alternately

on the outside and inside of the screen (3-4 times each). If the Filter Screen shows signs of damage, it should be replaced. Periodic cleaning

of the filter screen is necessary for removal of trapped particles.

WARNING

It is dangerous to open the filter while under pressure

De-Pressurizing the System

1.

Close Inlet and Outlet isolation valves .

2.

Perform Manual Backwash from the Filtron 1-10 Backwash controller by pressing the M

button

or from the irrigation controller (HN-G-01-2-XXX HN-G-02-2-XXX models only)

.

3.

Verify pressure has been released running a second backwash and observing no

backwash flow, or by checking the reading on the pressure gauges (if installed).

4.

(HN-G-01-1-XXX HN-G-02-1-XXX models only)

- Remove Low Pressure 5/16” plastic

tube from the Inlet to release the pressure and drain the HN-G filter.

5.

(HN-G-01-2-XXX HN-G-02-2-XXX models only)

- Remove the

1/4" Tubing

from filter flush port.

6.

Disconnect the drain pipe from the Drain valve at the union connection.

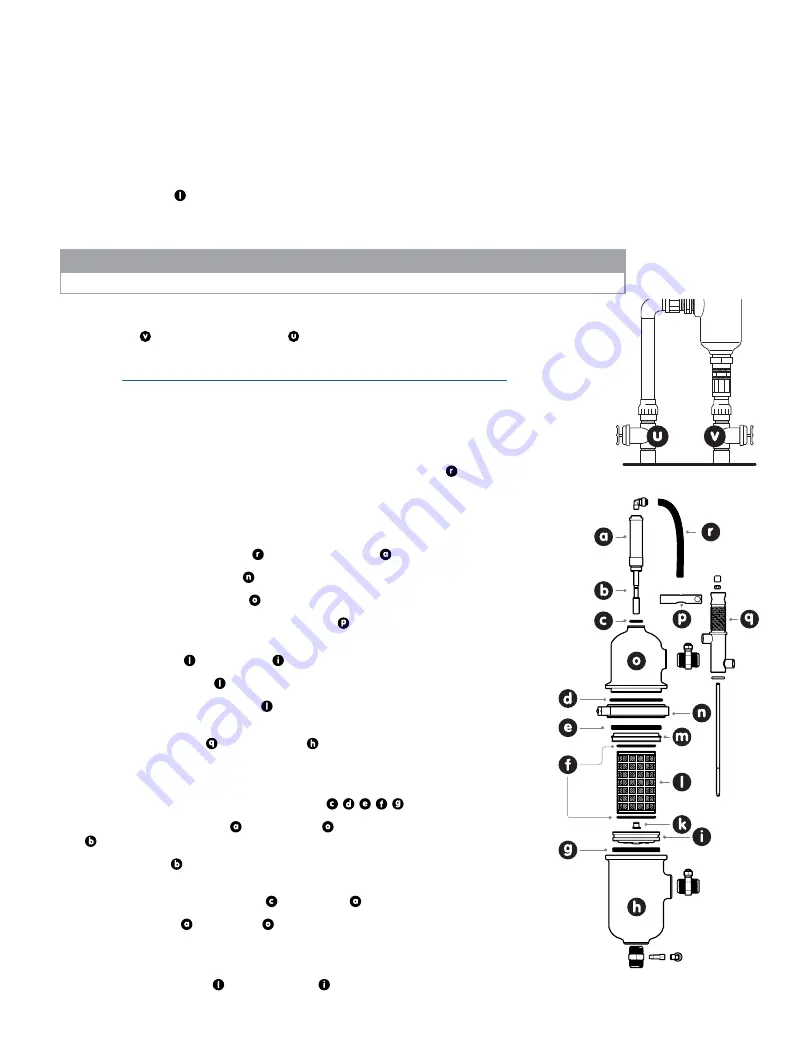

5.1.1 Disassembly

7.

Disconnect the ¼”

Plastic Tubing

connecting the

Piston

to the drain outlet.

8.

Release and remove the

Clamp

.

9.

Carefully remove the filter

Cover

.

10.

Carefully hold and pull up on the

Hydraulic Motor

.

11.

This will remove the collector assembly, giving you access

to the

Filter Screen

, and

Inlet Disc

.

12.

Remove the

Filter Screen

.

13.

Inspect and clean the

Filter Screen

, using a pressure washer as necessary.

14.

Inspect and remove any foreign objects or large particles from

the

Collector Assembly

and the

Housing

.

5.1.2

Lubrication

15.

Grease (silicone recommended) all rubber parts: , , , , .

16.

Carefully unscrew the

Piston

from the

Cover

, clean and grease

Piston Shaft

(silicone grease recommended). Make sure the

Piston Shaft

moves freely.

17.

The

Piston Shaft

should be cycled in and out a few times to get the grease distributed

to the inner O-ring seal. Two applications of grease and cycling is adequate.

18.

Clean and grease the

Piston O-Ring

on the

Piston

.

19.

Replace the

Piston

on the

Cover

, hand tighten only, no tools.

5.1.3

Re-assembly

20.

Replace the

Filter Screen

into the

Inlet Disc