For DVH kits:

4. Use 4 inch diameter flex pipe that is provided in the kit or a comparable single wall metal pipe. The

maximum allowable length of intake pipe is ten feet not including elbows.

5. Begin installing the 4” tee to the burner (Riello and Heat Wise require the supplied 3” to 4” increaser to be

installed first). Secure all joints on the intake with three screws each.

6. Install the supplied vacuum relief damper in the branch of the tee making sure that it is mounted with all

labeling right side up and perfectly horizontal.

7. Off of the last leg of the tee install the 4” duct elbow, and then the aluminum flex pipe.

8. Finally attach the other end of the flex pipe to the intake hood or intake port on the concentric hood.

9. Inspect the intake system and make sure all connections are secure and then seal each joint with silicone or

aluminum tape.

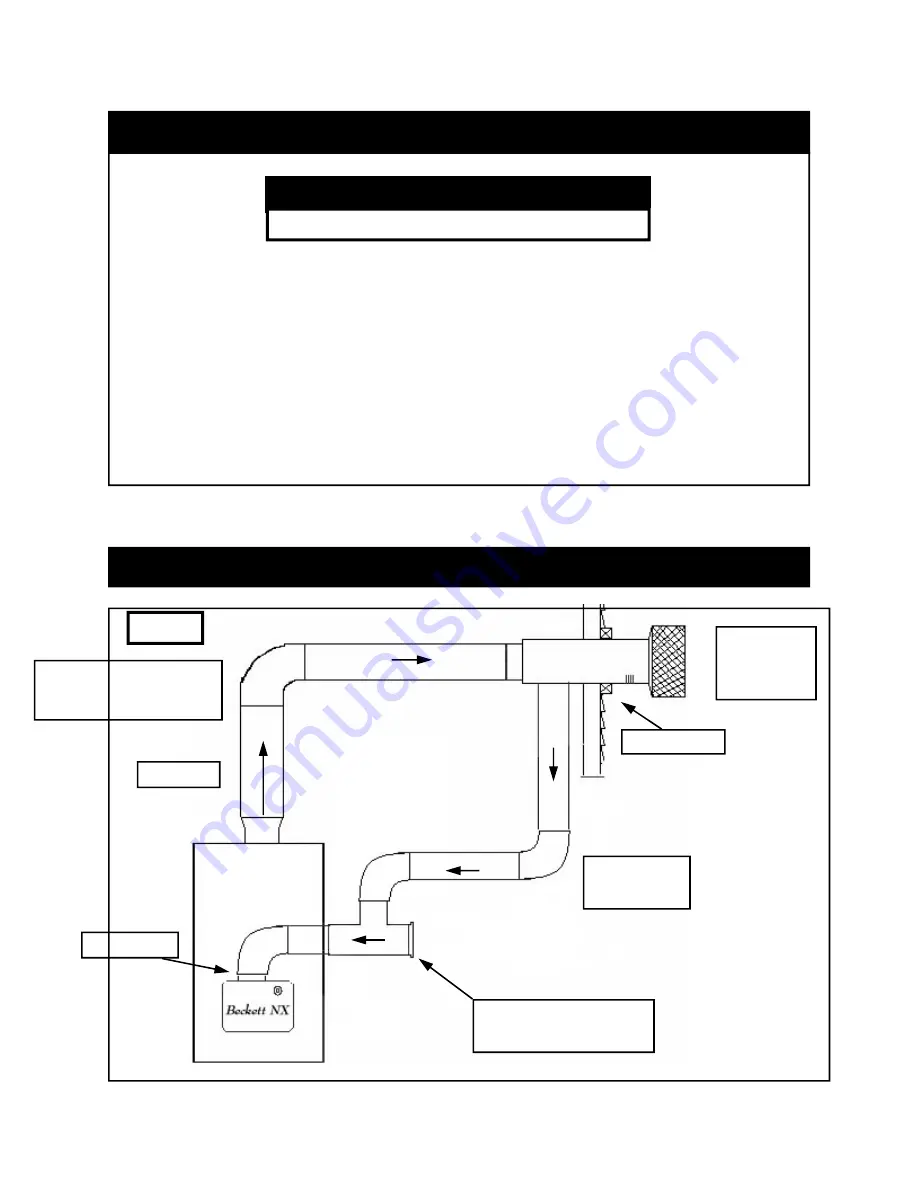

2.2 Installation of Make-up Combustion Air

NOTICE

Do not operate the burner with air intake disconnected.

9

Vent Connector

Must Be Sealed Design

Air Boot

Exhaust

Combustion

Air

Positive

Pressure

Oil Fired

2.3 Vent System Diagram

DVH-5

2” X 2” Frame

Direct Vent

System

Terminal

Vacuum Relief Valve

(w/ RC-4 Damper)

Содержание Air Compressor

Страница 2: ......

Страница 19: ...4 Wiring 16 Riello Burner with post purge control multi zone control wiring...