SIEPYEUOQ2A01G AC Drive Q2A Technical Manual

303

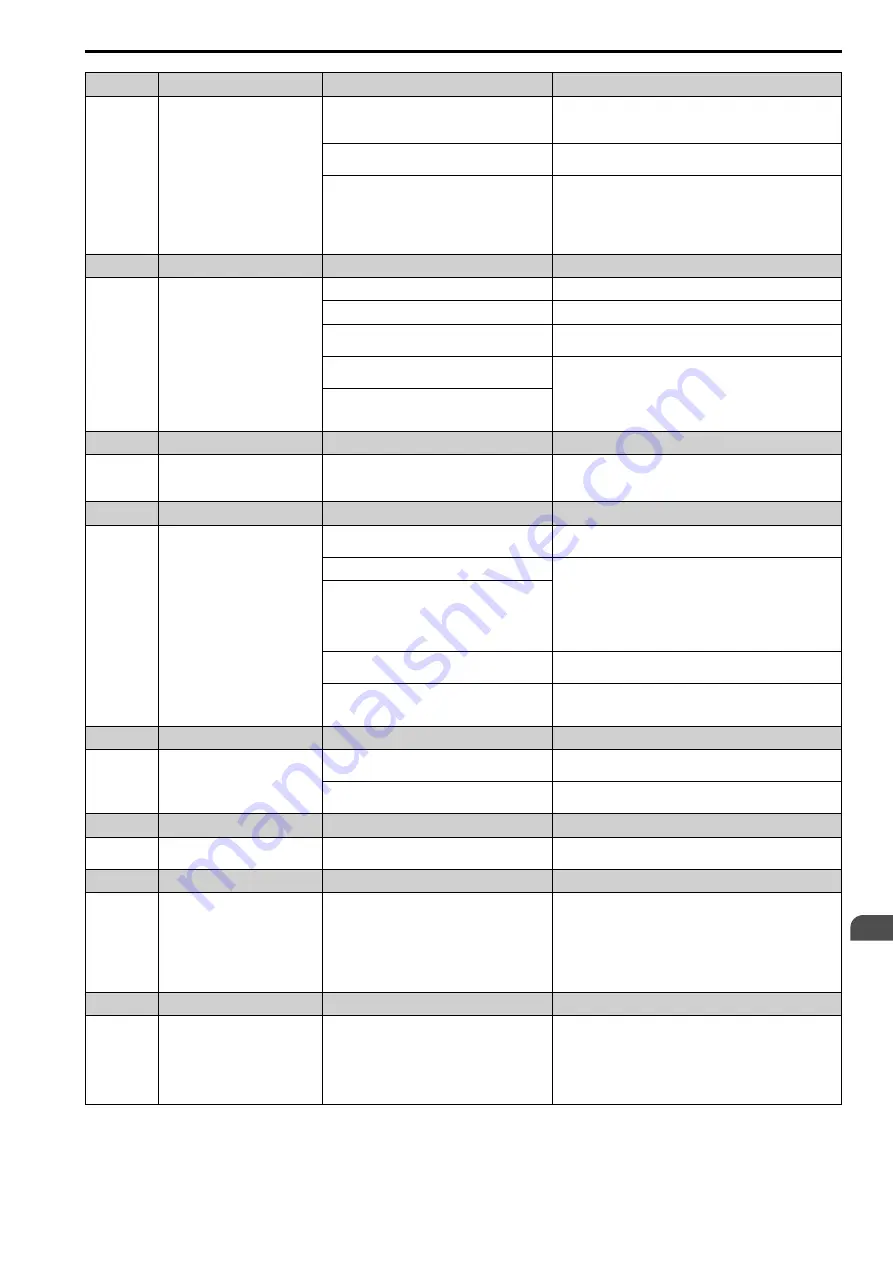

Code

Name

Causes

Possible Solutions

Er-09

Acceleration Error

The motor did not accelerate for the specified

acceleration time.

1.

Increase the value set in

C1-01 [Accel Time 1]

.

2.

Disconnect the machine from the motor and do Rotational

Auto-Tuning again.

The value of

L7-01 [FW Torque Limit] or L7-02

[RV Torque Limit]

is small.

Increase the value set in

L7-01 or L7-02

.

Rotational Auto-Tuning was done with a load that

was more than 30% of the rating connected to the

motor.

•

Disconnect the machine from the motor and do Rotational

Auto-Tuning again.

•

If you cannot uncouple the motor and load, make sure that the

load is less than 30% of the motor rating. If a mechanical

brake is installed in the motor, release the brake during

Rotational Auto-Tuning.

Code

Name

Causes

Possible Solutions

Er-10

Motor Direction Error

There is defective drive and motor wiring.

Examine and repair motor wiring.

There is defective drive and encoder wiring.

Examine and repair the wiring to the encoder.

The direction of the motor and the setting of

F1-05

[Enc1 Rotat Selection]

are opposite.

Set

F1-05

correctly.

The machine pulled the motor to rotate in the

opposite direction.

When the torque reference is 100% or higher, the

sign of the speed reference was opposite of the

detected speed.

Disconnect the machine from the motor and do Rotational Auto-

Tuning again.

Code

Name

Causes

Possible Solutions

Er-11

Motor Speed Error

The torque reference during acceleration is too high

(100%).

•

Increase the value set in

C1-01 [Accel Time 1]

.

•

Disconnect the machine from the motor and do Rotational

Auto-Tuning again.

Code

Name

Causes

Possible Solutions

Er-12

Current Detection Error

There is a phase loss in the drive input power. (U/

T1, V/T2, W/T3)

Examine and repair motor wiring.

The current exceeded the current rating of the drive.

The output current is too low.

•

Check the motor wiring for any short circuits between the

wires.

•

Check and turn ON any magnetic contactors used between

motors.

•

Replace the control board or the drive. For information about

replacing the control board, contact the manufacturer or your

nearest sales representative.

You tried Auto-Tuning without a motor connected

to the drive.

Connect the motor and do Auto-Tuning.

There was a current detection signal error.

Replace the control board or the drive. For information about

replacing the control board, contact the manufacturer or your

nearest sales representative.

Code

Name

Causes

Possible Solutions

Er-13

Leakage Inductance Error

The motor rated current value is incorrect.

Correctly set the rated current indicated on the motor nameplate

and perform Auto-Tuning again.

The drive could not complete tuning for leakage

inductance in fewer than 300 seconds.

Examine and repair motor wiring.

Code

Name

Causes

Possible Solutions

Er-14

Motor Speed Error 2

The motor speed was more than two times the

amplitude of speed reference during Inertia Tuning.

Decrease the value set in

C5-01 [ASR PGain 1]

.

Code

Name

Causes

Possible Solutions

Er-15

Torque Saturation Error

During Inertia Tuning, the output torque was more

than the value set in Torque Limit

L7-01 to L7-04

.

•

Increase the value set in

L7-01 [FW Torque Limit], L7-02 [RV

Torque Limit], L7-03 [FW Reg. TrqLimit], and L7-04 [RV Reg.

TrqLimit]

as much as possible.

•

Decrease the values set for the frequency and amplitude of the

test signals used when doing inertia tuning. First, decrease the

test signal amplitude, and then do Inertia Tuning. If the error

continues, decrease the test signal frequency and do Inertia

Tuning again.

Code

Name

Causes

Possible Solutions

Er-16

Inertia ID Error

The inertia found by the drive was too small or too

large during Inertia Tuning (10% or less, or

50000% or more).

•

Decrease the values set for the frequency and amplitude of the

test signals used when doing inertia tuning. First, decrease the

test signal amplitude, and then do Inertia Tuning. If the error

continues, decrease the test signal frequency and do Inertia

Tuning again

•

Correctly set the motor inertia as specified by the motor, and

do Inertia Tuning again.

Содержание Q2A

Страница 2: ...This Page Intentionally Blank 2 SIEPYEUOQ2A01G AC Drive Q2A Technical Manual...

Страница 12: ...12 SIEPYEUOQ2A01G AC Drive Q2A Technical Manual...

Страница 18: ...i 2 Legal Information 18 SIEPYEUOQ2A01G AC Drive Q2A Technical Manual...

Страница 28: ...1 2 Features and Advantages of Control Methods 28 SIEPYEUOQ2A01G AC Drive Q2A Technical Manual...

Страница 64: ...2 9 Installation Methods 64 SIEPYEUOQ2A01G AC Drive Q2A Technical Manual...

Страница 166: ...4 9 Test Run Checklist 166 SIEPYEUOQ2A01G AC Drive Q2A Technical Manual...

Страница 172: ...5 2 European Standards 172 SIEPYEUOQ2A01G AC Drive Q2A Technical Manual...

Страница 173: ...Standards Compliance 5 5 2 European Standards SIEPYEUOQ2A01G AC Drive Q2A Technical Manual 173...

Страница 174: ...5 2 European Standards 174 SIEPYEUOQ2A01G AC Drive Q2A Technical Manual...

Страница 175: ...Standards Compliance 5 5 2 European Standards SIEPYEUOQ2A01G AC Drive Q2A Technical Manual 175...

Страница 176: ...5 2 European Standards 176 SIEPYEUOQ2A01G AC Drive Q2A Technical Manual...

Страница 258: ...6 2 Modbus Communications 258 SIEPYEUOQ2A01G AC Drive Q2A Technical Manual...

Страница 356: ...8 7 Storage Guidelines 356 SIEPYEUOQ2A01G AC Drive Q2A Technical Manual...

Страница 357: ...SIEPYEUOQ2A01G AC Drive Q2A Technical Manual 357 9 Disposal 9 1 Safety Precautions 358 9 2 Disposal Instructions 359...

Страница 360: ...9 2 Disposal Instructions 360 SIEPYEUOQ2A01G AC Drive Q2A Technical Manual...

Страница 526: ...11 20 Parameters Changed by PM Motor Code Selection 526 SIEPYEUOQ2A01G AC Drive Q2A Technical Manual...