4.1

Wiring

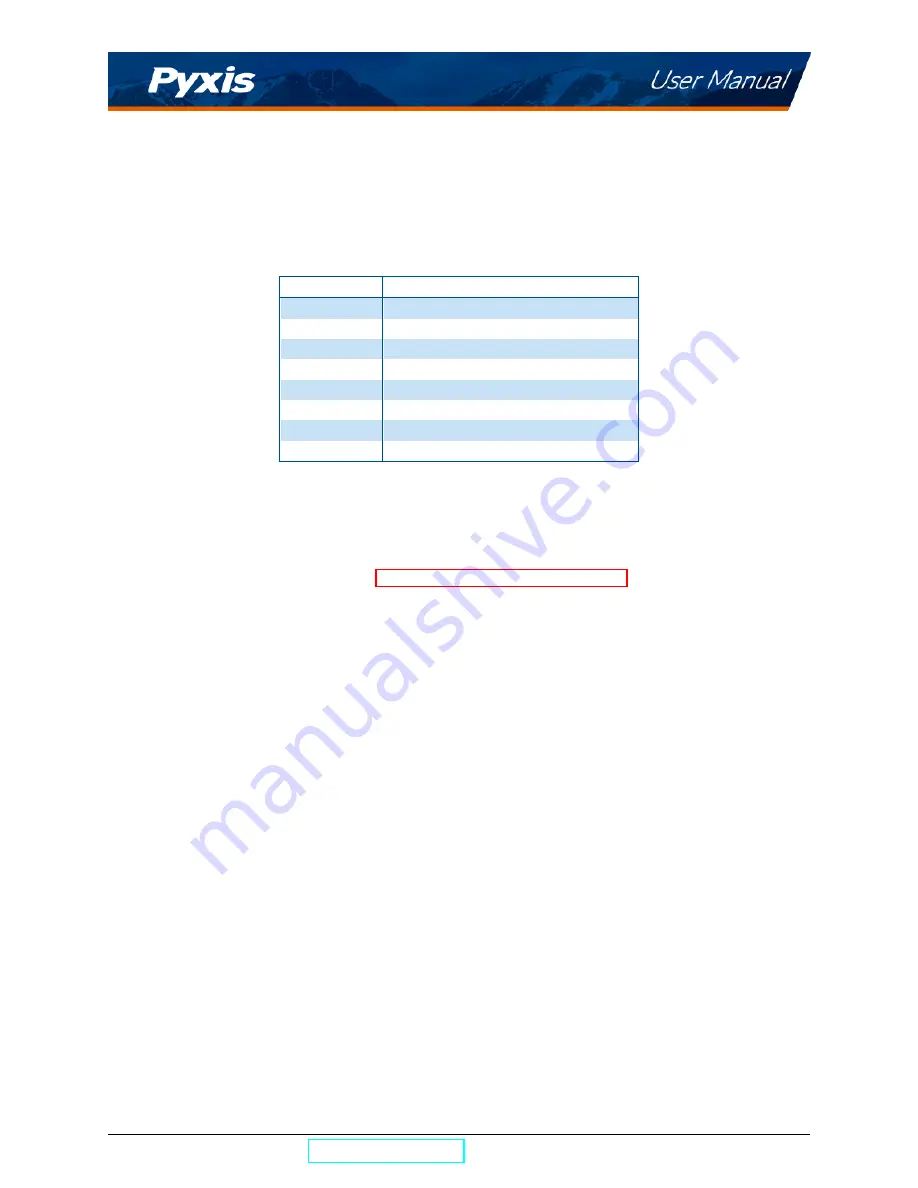

Follow the wiring table below to connect the CR-301 sensor to a controller. The Grey wire and the Brown

wire are the power ground and internally connected. The Grey wire can be used for the 4–20 mA return.

The Blue and Yellow wires are for RS-485 connection only and only required if using Modbus protocol. The

Green earth ground wire should be connected to the controller chassis ground if it is available.

Table 2.

Wire Color

Designation

Red

24V +

Brown

24V Power ground

White

General corrosion rate, 4–20mA +

Pink

Localized corrosion rate, 4–20mA +

Gray

*

4–20mA -

Blue

RS-485 A

Yellow

RS-485 B

Green

Shield, earth ground

*

Internally connected to the power ground

The CR-301 comes with 4–20mA transmitters embedded in the sensor body. It provides outputs on two

channels of 4–20mA signals that represent general corrosion rate and localized corrosion rate respectively.

Default alloy factors and corrosion rate scales in mils per year (MPY) are pre-programmed for each metal-

lurgy in the uPyxis APP as outlined in the

Test Metal Electrode Default Settings

table. When a metallurgy is

selected from the drop-down list, the uPyxis APP will automatically assign default alloy factor and 4–20mA

scales for both general and localized corrosion. The corrosion rates scales provided by uPyxis are commonly

appropriate for the range of typical corrosion observed of the selected metallurgy, however, the user may

desire to alter the alloy factor or corrosion rate scale for any selected metallurgy in the uPyxis APP.

The user may alter the 4–20 mA output from the CR-301 to a desired corrosion rate in the unit of MPY

by setting up one of three configurable parameters. The configurable parameters include 1) alloy factor,

2) the sensor’s 4–20 mA range and 3) the controller’s 4–20 mA range. The first two reside in the CR-301

sensor itself and can be configured by using the uPyxis app.

CR-301 User Manual

| +1 (866) 203-8397

7

Содержание 51021

Страница 1: ......