11

ATTENTION: in case of detecting that the treated

water does not comply with the current national

legislation, re-perform the measurement. If the pro-

blem persists, close the inlet valve of the equipment,

open the tap, disconnect it electrically and

contact your technical support.

• Finally, clean the inside and bottom of the equipment

with single-use kitchen roll, in order to remove the wa-

ter that could have fallen onto it, as it could cause a

false alarm and blockage of the system.

7. MAINTENANCE

ATTENTION: Some components of your equip-

ment, such as pre-filters and membrane, are

consumables that have a limited duration.

The duration will depend on the quality of the local wa-

ter, consumption, type of use and specific aspects of

the water to be treated such as extreme turbidity, high

chlorination, excess iron, etc.

ATTENTION: In order to guarantee the quality of

the water supplied by your equipment, it must be

periodically maintained.

6. COMMISSIONING

6.1. FILTER RINSING

• It is necessary to remove dust and carbon grains from

the filter that is generated during transport and hand-

ling of the equipment and corresponding. This dust

must be eliminated since it could partially or comple-

tely obstruct the membrane as well as cause a malfunc-

tion of the equipment. To do this, first open the water

faucet. According to the appliance electrically. Then

press the power button for 1.5 seconds. The unit will

rinse the filters.

6.2. SANITIZATION OF EQUIPMENT

• Perform a sanitization of the equipment, according to

the model and procedure indicated by the manufactu-

rer (see the Sanitization Procedure). If you have any

questions, contact your dealer.

6.3. SYSTEM TIGHTNESS, SHUTDOWN AND START-UP

· Close the equipment tap on the worktop and keep the

equipment hydraulically or electrically powered by ca-

rrying out an ocular check of the system to ensure that

8

9

10

there are no leaks (for 5 min approx.)

Open the dispenser faucet. The equipment should start

and supply water. Turn off the faucet again and check

that the equipment stops.

6.4. RINSING AND CLEANING

• Open the equipment faucet and measure the quality

of the water being produced with a conductivity meter

or TDS, check that the salt reduction obtained is ade-

quate with respect to the water to be treated (14).

12

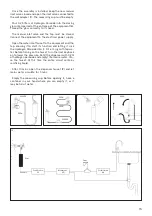

5.2. INSTALLATION OF FILTERS

• Remove protective plastic from filters.

· Install pre-filter number 1 (PP+CB) in position.

· Enter it as shown in the image (8) and make a 90º turn so

that it is correctly installed (9 and 10).

· Perform the same procedure with the other filters by gui-

ding the sequence of numbers.

· After you complete the installation of the filters, open the

inlet valve and equipment rinse faucet during 10 minutes.

Содержание VYRTA direct flow

Страница 1: ...1 USER MANUAL EQUIPMENT REVERSE OSMOSIS ...

Страница 2: ......

Страница 3: ...Index P 1 2 3 4 User manual Technical manual Sanitation procedure Technical Data sheet 4 8 14 19 ...

Страница 13: ...13 IN FEED DRAIN 3 8 1 4 RO 3 8 1 4 1 4 1 4 1 4 Hydraulic scheme ...

Страница 17: ...17 ...

Страница 28: ...NOTES ...

Страница 29: ...NOTES ...

Страница 30: ...NOTES ...

Страница 31: ...NOTES ...

Страница 32: ...MU RO VYRTA DIRECT FLOW 2021 910475 ...