17

COMMUCATION WITH SOFTWARES

The weighing computer Advance Super USB can work with the software

SUPER DATA MIX

or

PTM

MANAGEMENT

, which allows the exchange of programmings and loading and unloading data, the best

management of the quantities of material, and the control on the operator's work on the wagon.

Here under you'll find some useful advice to communicate with the program.

In order to communicate with the program, it is necessary to get a USB pendrive (supplied as standard

equipment with the scale), and get in the total weight menu.

In order to download data from the program into the weighing computer, get in the total weight menu and

put the USB pendrive in the specific connector.

In order to export loading and unloading data, as well as changes made on groups and recipes, get in the

total weight menu and put the USB pendrive in the specific connector.

Check that the USB pendrive has been put in the weighing computer in the right way.

Do not switch off the weighing computer while sending/receiving data.

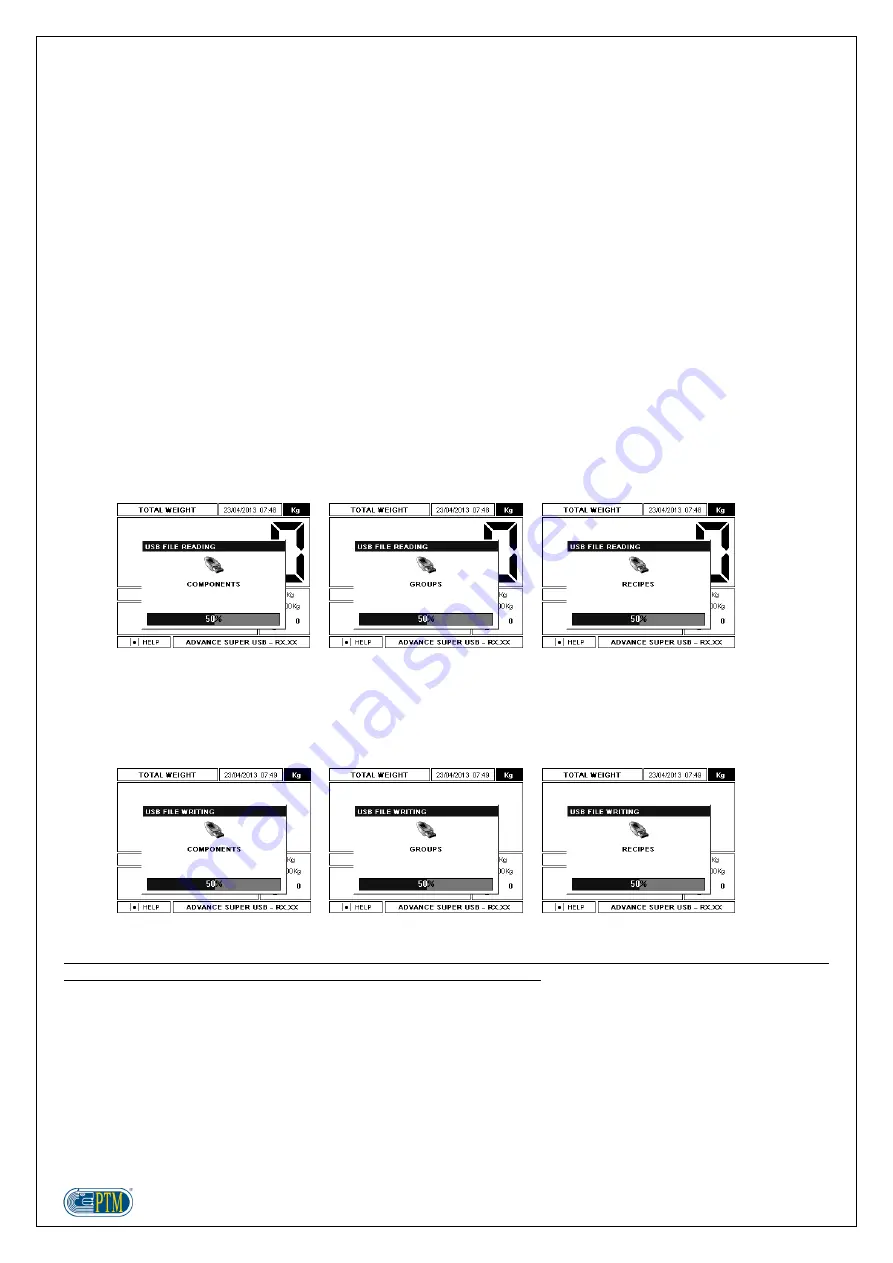

Here is the detailed procedure for sending/receiving data:

Create the programmings with the software Super Data Mix or PTM Management

Send the programmings from the software Super Data Mix or PTM Management to the weighing computer

by inserting the USB pendrive in the specific connector.

Get in the total weight menu and insert the USB pendrive.

Wait for the data to be automatically downloaded.

Take out the USB pendrive and carry out the loading/unloading operations.

On the weighing computer it is possible to create or modify components, groups and recipes; all changes

will be then exported to the USB pendrive and imported into the program Super Data Mix or PTM

Management.

Wait for the data to be automatically downloaded upon putting the USB pendrive in the specific connector.

ATTENTION: if the communication between scale and software fails, and data go lost, they can be retrieved as

backup data from the internal memory of the scale (see BACKUP USB).