16

SERVICE AND ADJUSTMENTS

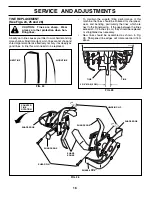

FIG. 26

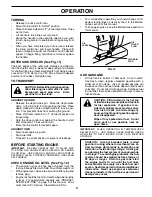

TINE REPLACEMENT

(See Figs. 24, 25 and 26)

CAUTION: Tines are sharp. Wear

gloves or other protection when han-

dling tines.

A badly worn tine causes your tiller to work harder and dig

more shallow. Most important, worn tines cannot chop and

shred organic matter as effectively nor bury it as deeply as

good tines. A tine this worn needs to be replaced.

FIG. 25

• To maintain the superb tilling performance of this

ma chine the tines should be checked for sharpness,

wear, and bending, particularly the tines which are

next to the transmission. If the gap between the tines

ex ceeds 3-1/2 inches (9 cm), they should be replaced

or straight ened as necessary.

• New tines should be assembled as shown in Fig.

28. Sharp ened tine edges will rotate rearward from

above.

tine_3

3-1/2" MAX (9 CM)

tine_13

HAIRPIN CLIP

SHARP

EDGES

COUNTER

TINE

ROTATION

SHARP EDGE

SHARP EDGE

SHARP EDGE

SHEAR PIN

SHARP EDGE

FIG. 24

NEW TINE

WORN TINE

TINE

TINE

SHARP EDGE

0205

0