FUEL SYSTEM/CARBURETION

4.5

CV CARBURETOR SYSTEM

FUNCTION

Carburetor Component Function

System

Main

Components

Main

Function

Main

Affect

Float

System

(Level Control)

Inlet Pipe,

Needle and

Seat, Float,

Float Pin

Maintains

specified

fuel level in

float cham-

ber (carbu-

retor float

bowl)

All systems

All throttle

ranges

Venting

Passages in

Carburetor,

Vent lines

to frame

Supplies

atmospheric

pressure to

float cham-

ber

All systems

All throttle

ranges

Starter

(Choke/En-

richment)

Choke Lever,

Cable, Plung-

er, Return

Spring, Carb

Passages

(Starter Jet,

Starter Bleed

Pipe)

Supplies

additional

fuel air mix-

ture neces-

sary for cold

starting

All throttle

ranges

Greatest ef-

fect at low

throttle set-

tings and

idle

Pilot (Idle

System)

Pilot Jet/

Passage-

ways, Pilot-

Mixture

Screw with

Spring

Washer and

Sealing O-

Ring, By-

pass Ports

(Behind

Throttle

Plate), Pilot

Air Jet, Pilot

Outlet,

Throttle

Plate

Primarily

supplies fuel

at idle and

low throttle

positions

Mainly idle

to 1/4

throttle

Minimal ef-

fect after 1/2

throttle

Main Sys-

tem

Main Jet,

Main Air Jet,

Main Air

Passage,

Needle Jet,

Jet Needle,

Vacuum

Slide,

Throttle

Plate

Supplies

fuel at mid-

range and

high throttle

settings.

1/4 to full

throttle

VENT SYSTEMS - CV

CARBURETOR

The carburetor float bowl vent lines supply

atmospheric pressure to the float bowl. The lines

must be free of kinks, restrictions and be properly

routed. This allows fuel to flow in the proper amount

and prevents contaminants from entering the

carburetor.

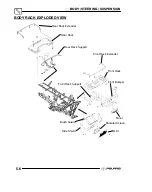

MIKUNI CV CARB

OPERATION

The constant velocity carburetor incorporates a

mechanically operated throttle plate and a vacuum

controlled slide valve (vacuum slide). The venturi

cross-sectional area in the carburetor bore is

increased or decreased automatically by the vacuum

slide, which moves according to the amount of

negative pressure (less than atmospheric) present in

the venturi.

A diaphragm attached to the top of the vacuum slide

is sealed to the slide and to the carburetor body

forming two chambers. The chamber above the

diaphragm is connected to the venturi area by a drilled

orifice in the center of the vacuum slide. The chamber

below the diaphragm is vented to atmospheric

pressure by a passage on the air box side of the

carburetor. A spring, installed in the center of the

vacuum slide, dampens the slide movement and

assists the return of the slide.

= Air Flow

= Low Pressure

Air Box

Pressure

From

Air Box

Venturi

Throttle

Plate

Diaphragm

Vacuum

Slide

Low Pressure

From Venturi

Содержание 600 Dragon SP

Страница 1: ...2004 SPORTSMAN 600 700 SERVICE MANUAL PN 9918803 ...

Страница 138: ...BODY STEERING SUSPENSION 5 16 NOTES ...

Страница 210: ...FINAL DRIVE 7 38 NOTES ...

Страница 293: ...ELECTRICAL 10 43 WIRING DIAGRAM HAND AND THUMB WARMERS WINCH HUNTER EDITION ...

Страница 294: ...ELECTRICAL 10 44 NOTES ...

Страница 295: ...ELECTRICAL WIRING DIAGRAM EARLY 2004 SPORTSMAN 600 700 BUILT BEFORE FEB 20 2003 Built Before February 20 2003 ...

Страница 297: ...ELECTRICAL WIRING DIAGRAM LATE 2004 SPORTSMAN 600 700 BUILT AFTER FEB 20 2003 Built After February 20 2003 ...

Страница 298: ...ELECTRICAL WIRING DIAGRAM LATE 2004 SPORTSMAN 600 700 BUILT AFTER FEB 20 2003 Built After February 20 2003 NOTES ...

Страница 299: ...ELECTRICAL WIRING DIAGRAM LATE 2004 SPORTSMAN 600 700 MODELS WITH FUEL GAUGE Models Equipped with Fuel Gauge ...

Страница 300: ...ELECTRICAL WIRING DIAGRAM LATE 2004 SPORTSMAN 600 700 MODELS WITH FUEL GAUGE NOTES ...

Страница 301: ...ELECTRICAL WIRING DIAGRAM 2004 SPORTSMAN 600 700 HUNTER EDT HAND WARM WINCH ...

Страница 307: ...Winch Switch Installation 10 34 Winch Wiring 10 35 Wiring Diagram Hand Thumb Warmer Winch 10 43 ...

Страница 308: ...PN 9918803 Printed in USA ...