Mounting and rigging options

WARNING

!

The overhead suspension of loudspeakers is a very serious issue with potentially lethal consequences should anything go wrong. Rigging should only be carried out

by experienced personnel following safe working practice. Should you be in any doubt whatsoever, please contact the retailer or dealer from which you purchased this

product.

!

When utilising any suspension method, a secondary safety feature must be used. For any suspension method, fit a rigging equipment to any of the rigging points. A

safety wire can then be attached to this and connected to your safety point. If you are in any doubt whatsoever about how to safety suspend your loudspeakers, do not

hesitate to contact the retailer or dealer from which you purchased this product.

!

Be sure to provide double safety with reference to the XY-Series Installation Manual found at these products support site.

!

With any suspension method, a second anchor point should be used as safety feature.

!

Do not use the double safety hoisting accessory enclosure connection together with the main hoisting accessory connection.

!

After installing the speaker, never loosen any of its screws, since the speaker could fall or other accidents could occur.

!

After installation, you must confirm that the speakers are safely installed. You must also periodically check them to make sure that they are still safe.

!

You must confirm that the speakers are safely installed after earthquake.

Rigging hardware

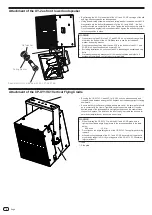

The XY-1 and XY-2E have multiple options for mounting and suspension, both for temporary use and for

permanent, fixed installation.

The XY-1 and XY-2E contain 2 kinds of M10 threaded fixing points around the enclosure.

Hexagon socket countersunk bolts are attached to the 22 M10 threaded fixing points by factory default, and

the speakers can be suspended from these fixing points by using forged shoulder eyebolts and the optional

flying hardware.

The structure of the M10 threaded fixing points are such that their attached bolts pierce through the speaker

enclosure. Therefore, if these points will not be used, the holes must be blocked with the hexagon socket

countersunk bolts attached by factory default to ensure that the enclosure is completely sealed. If the holes

for metal fittings are left open, the sound quality of the speakers will be affected.

Also, the eyebolts used for these fixing points must be long enough such that at least 25 mm of the thread

cutting enters the speaker enclosure. If the bolts are not long enough, there may be a risk of damage to

various parts, falling of the speakers, etc.

These fixings allow suspension in any orientation, with the extra point on the rear of the enclosure available

for pull-back to obtain the desired rigging angle or as a secondary safety point.

In the installation, ensure tighten the bolts following torques.

M10 bolts : 15 N·m

The XY-1 and XY-2E are equipped with a M10 threaded boss that allows for the attachment of the XY-2 to the

center of their bottom surfaces.

This fixing point is specially for the attachment of the XY-2. Do not use it for any other applications.

Precautions when installed in high locations

Any installation (permanent or temporary) must be securely attached to the structure of the building using chain, steel wire or web straps that are certified and load rated

for the loudspeaker system. Consideration must be taken when determining the loading on the structure to include loudspeakers and rigging hardware, and the appropriate

safety factor can then be decided upon. If you are in any doubt whatsoever, please contact the retailer or dealer from which you purchased this product. A reputable rigging

organisation should also be able to advise on legislation regarding safety factors for suspended systems of this type.

7

Engb

Mo

un

tin

g an

d ri

gg

in

g o

pti

on

s

Nut

Eyebolt

Threaded fixing point

25 mm

(1.0 in.)