6. Fit the separator cover plate with new flat seal.

7. Tighten the screws on the separator cover plate evenly.

– Tightening torque:

21 Nm

.

During operation, the new exhaust filter becomes saturated with oil. It is therefore normal for the operat-

ing fluid fill level to drop slightly after the filters were changed.

7.5 Cleaning the intake strainer

The intake strainer in the vacuum connection upper section must be cleaned:

● when the throughput decreases

● if there is visible contamination

Required tool

● Hexagonal wrench,

WAF 13

1

2

3

4

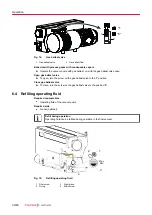

Fig. 20:

Dismantling / assembling the intake strainer

1 Cheesehead screw

3

Vacuum connection

2 Washer

4

Intake strainer

Dismantling the intake strainer

1. Dismantle the operating fluid return line from the vacuum connection.

2. Unscrew the cheesehead screws.

3. Remove the vacuum connection.

– Pay attention to the washers.

4. Remove the intake strainer from the intake duct.

5. Dismantle the part of the non-return valve resting in the intake duct.

Clean all parts and examine for wear

1. Clean all parts.

2. Examine all parts for wear.

Assembling the intake strainer

1. Mount the parts of the non-return valve.

2. Insert the intake strainer into the intake duct.

3. Fit the vacuum connection.

– Pay attention to the washers.

4. Screw on the cylinder screws.

5. Mount the operating fluid return line to the vacuum connection.

7.6 Cleaning the gas ballast filter

The gas ballast filter is soiled if the vacuum pump takes in ambient air containing dust during gas ballast

operation.

Maintenance

40/60

Содержание HENA 201

Страница 1: ...OPERATING INSTRUCTIONS EN Translation of the Original HENA 201 251 301 301 S Rotary vane pump ...

Страница 59: ...59 60 ...

Страница 60: ... PD0087 ed C Date 1910 P N PD0087BEN ...