3 Product description

3.1 Function

The rotary vane pumps of the HenaLine are single-stage, oil-sealed rotary positive displacement pumps

with air cooling and circulatory lubrication. A non-return valve in the vacuum connection closes the in-

take line automatically when the rotary vane pump is switched off and prevents an operating fluid return

flow. The integrated oil mist filter cleans the conveyed gas and prevents the operating fluid mist from

being emitted at the exhaust. An operating fluid filter is also installed for cleaning the operating fluid.

Fig. 2:

Operating principle

The pumping system is made up of the housing, the eccentrically mounted rotor, and the centrifugally

sliding vanes, which divide the suction chamber into multiple chambers. The volume of each chamber

changes periodically as the rotor rotates. This causes the gas to be continuously drawn in at the vac-

uum connection and compressed in the suction chamber by the rotation of the rotor until the exhaust

valve opens against the atmospheric pressure and the gas leaves the suction chamber.

1

2

3

4

5

6

7

8

12

11

10

9

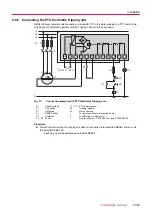

Fig. 3:

Structure of the rotary vane pump

1 Operating fluid separator

7

Sight glass

2 Vacuum connection

8

Operating fluid filter

3 Gas ballast valve

9

Motor

4 Exhaust connection

10

Motor terminal box

5 Filler screw with manometer

11

Intermediate flange

6 Drain screw

12

Axial fan with oil / air heat exchanger

3.1.1 Operating fluid

The pump oil, also known as operating fluid, fulfills various tasks in a rotary vane pump:

● lubrication of all moving parts

● filling part of the dead volume under the exhaust valve

● sealing the gap between the intake and exhaust channel, and between the vanes and the working

chamber

● ensuring an optimal temperature balance through heat transfer

Product description

16/60

Содержание HENA 201

Страница 1: ...OPERATING INSTRUCTIONS EN Translation of the Original HENA 201 251 301 301 S Rotary vane pump ...

Страница 59: ...59 60 ...

Страница 60: ... PD0087 ed C Date 1910 P N PD0087BEN ...