2

0

2

0

-0

3

20

Commissioning

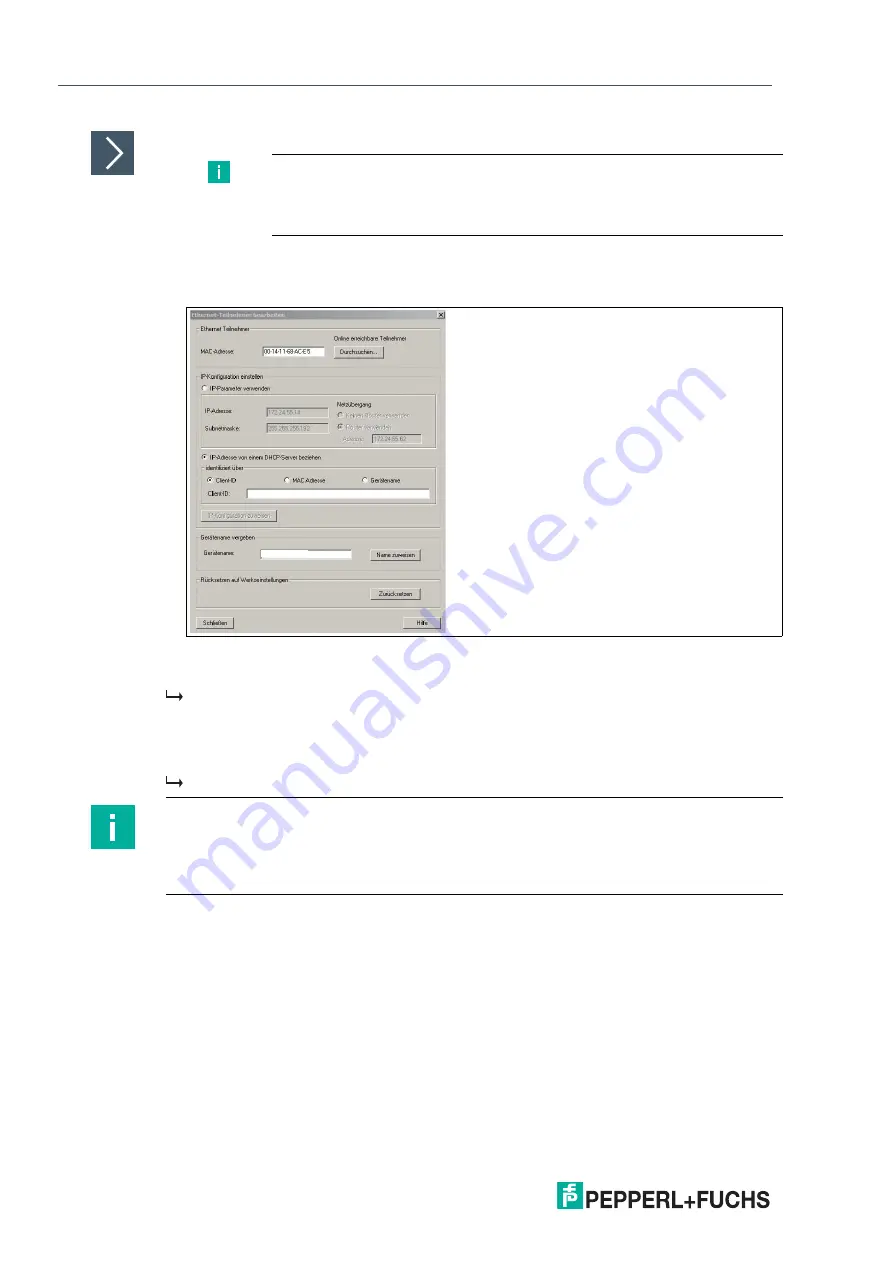

Changing the device name

1.

Stop PROFINET communication if it is active.

2.

Select

Fuchs WCS

from the list of nodes and click on

OK

.

3.

In the field

Assign device name

, enter the device name for the interface module. Click on

Assign Name

.

The interface module is given the name you entered and can then be uniquely identified by

the PLC.

4.

In the WCS module

Properties

window, enter the new device name and save the

configuration.

The PLC will recognize the name of the device and will be able to communicate with it.

Depending on your application, select one, two, three, or four connected WCS read heads and

the operating mode. When in the "only Position" operating mode, the WCS read heads output

their position. In the "Position and Speed" operating mode, the WCS read heads output their

position and the speed at which they are currently moving.

Regardless of the number of WCS read heads, 1 byte is reserved for querying the diagnostics

for the WCS read heads in the master. For the response data, 4 bytes are reserved for each

WCS read head in the "only Position" operating mode (configuration data for four WCS read

heads: 0x20, 0xD1, 0xD1, 0xD1, 0xD1). In the "Position and Speed" operating mode, 6 bytes

are reserved for each WCS read head (configuration data for four WCS read heads: 0x20,

0xD2, 0xD2, 0xD2, 0xD2).

Note

The PLC must not communicate with the device via PROFINET while you are

changing the device name. An error message will be output if you try to

change the device name while the plant is in operation.

Note

An LED on the device can be made to flash using the configuration tools. If you have a number

of WCS-PNG410 interface modules on the network, this function will enable to you to uniquely

identify each device. Select the device from the list of Ethernet modules and click

Flash

. The

"State" LED on the relevant WCS-PNG410 interface module will start to flash.