5.3 Connecting the Suction Hose

∙

!

WARNING

Cleanload Nexus must always be connected to

the sprayer suction to ensure effective emptying.

∙

It is recommended that the minimum system vacuum suction

is -0.75 bar.

∙

Where it is planned to use the Suction Hose for measuring

part containers, the hose should have sufficient. length so

that it can be raised above the Suction Hosetail Outlet when

measuring and lowered again for emptying.

∙

!

WARNING

Always ensure that the Suction Hose is secured

and does not present a hazard when transporting.

∙

!

WARNING

Replace the Suction Hose if it is damaged or

badly stained.

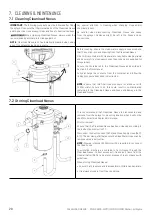

The Suction Hose is marked with stars (*). The distance between

stars represents 25 ml of liquid volume.

For convenience, a set of stickers is provided that can be fixed to

the Suction Hose to show the measured volume.

To apply a sticker, attach the side of the label with no text first,

then wrap the label back over itself and secure.

Attach the first sticker marked ‘200 ml’ so that it is covering the

* that is

4th from the end of the hose

as shown. 200 ml is the

lowest volume that can be measured.

Attach the other stickers aligned on the printed stars sequentially

up the length of the hose from the first 200 ml sticker.

4

5

6

A

-225ML

-275ML

200ml

-200ML

-250ML

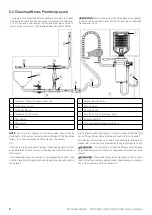

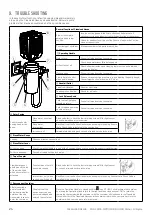

Place a hose clamp (Ref. 5) over the Suction Hose.

Connect the end of the labelled Suction Hose (Ref. 4) that reads

“200ml” to the Suction Hose Outlet (Ref. 6).

Push the Suction Hose (Ref. 4) firmly onto the Suction Hosetail

Outlet (Ref. 6) so that it is fully engaged to the Hosetail Length (A).

This is necessary for accurate measuring.

Secure the hose clamp (Ref. 5).

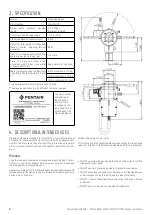

1

8

7

6

5

4

2

3

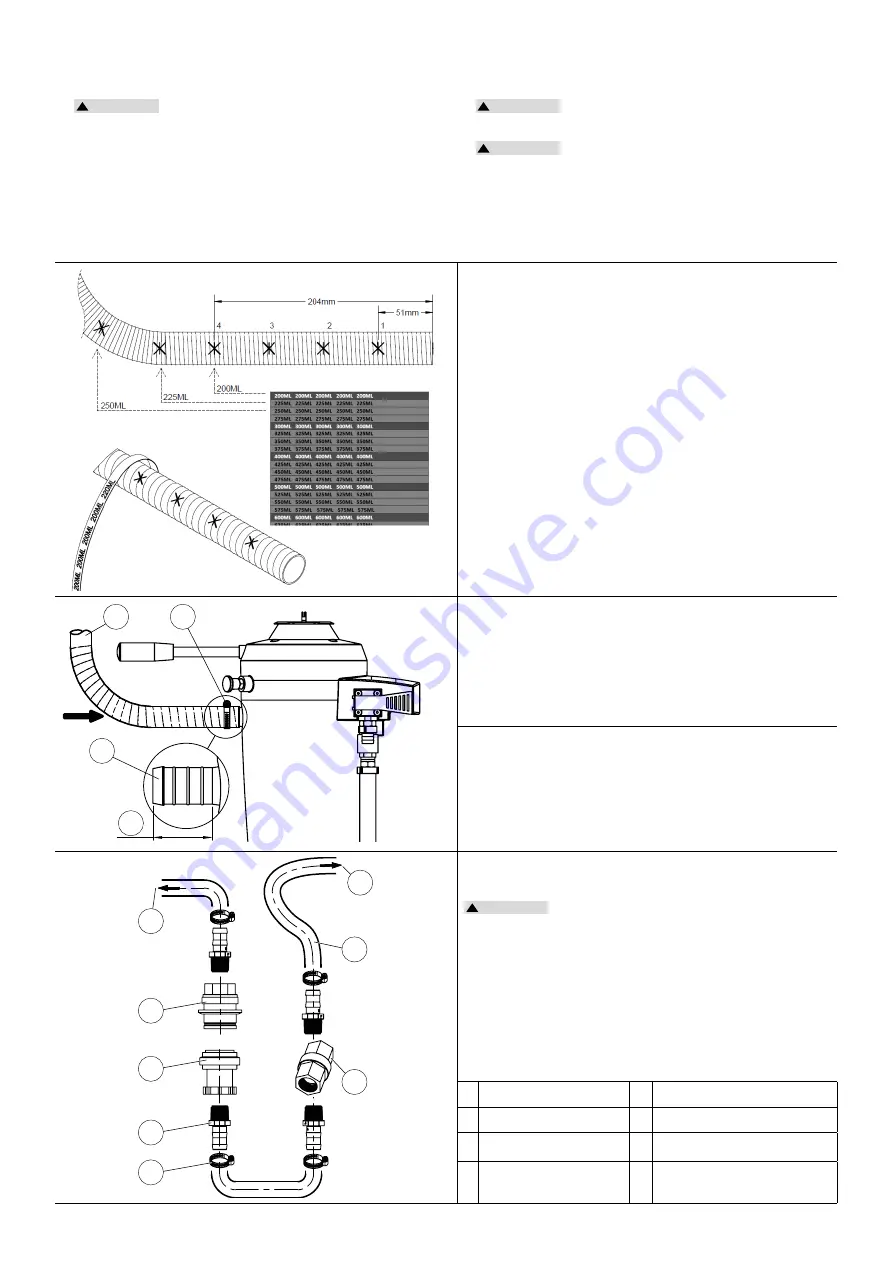

The other end of Suction Hose should be connected to the

suction line that supplies the sprayer tank.

!

WARNING

A suitable 1” check valve must be fitted in the

suction line to prevent the risk of backflow of line contents into

the Cleanload Nexus. The check valve should be fitted after the

measuring portion of the hose using suitable Hosetail adaptors/

clamps as shown in the diagram.

After rinsing, the Suction Hose should always be empty between

the check valve and the Cleanload Nexus.

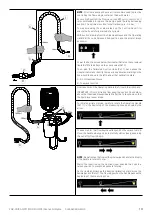

The diagram shows an example of a temporary suction

connection using suitable male and female dry break connectors.

These connectors are not included.

1

To CLEANLOAD NEXUS

5

1" Hosetail connector

2 Calibrated part of hose

6

Female dry break connector

3 Check valve

7

Male dry break connector

4 Hose clamp

8 To sprayer suction

CLEANLOAD NEXUS

PNR-CN100-OIPM (10/12/21) ©2021 Pentair. All Rights.

9