1

2

3

4

TM060220

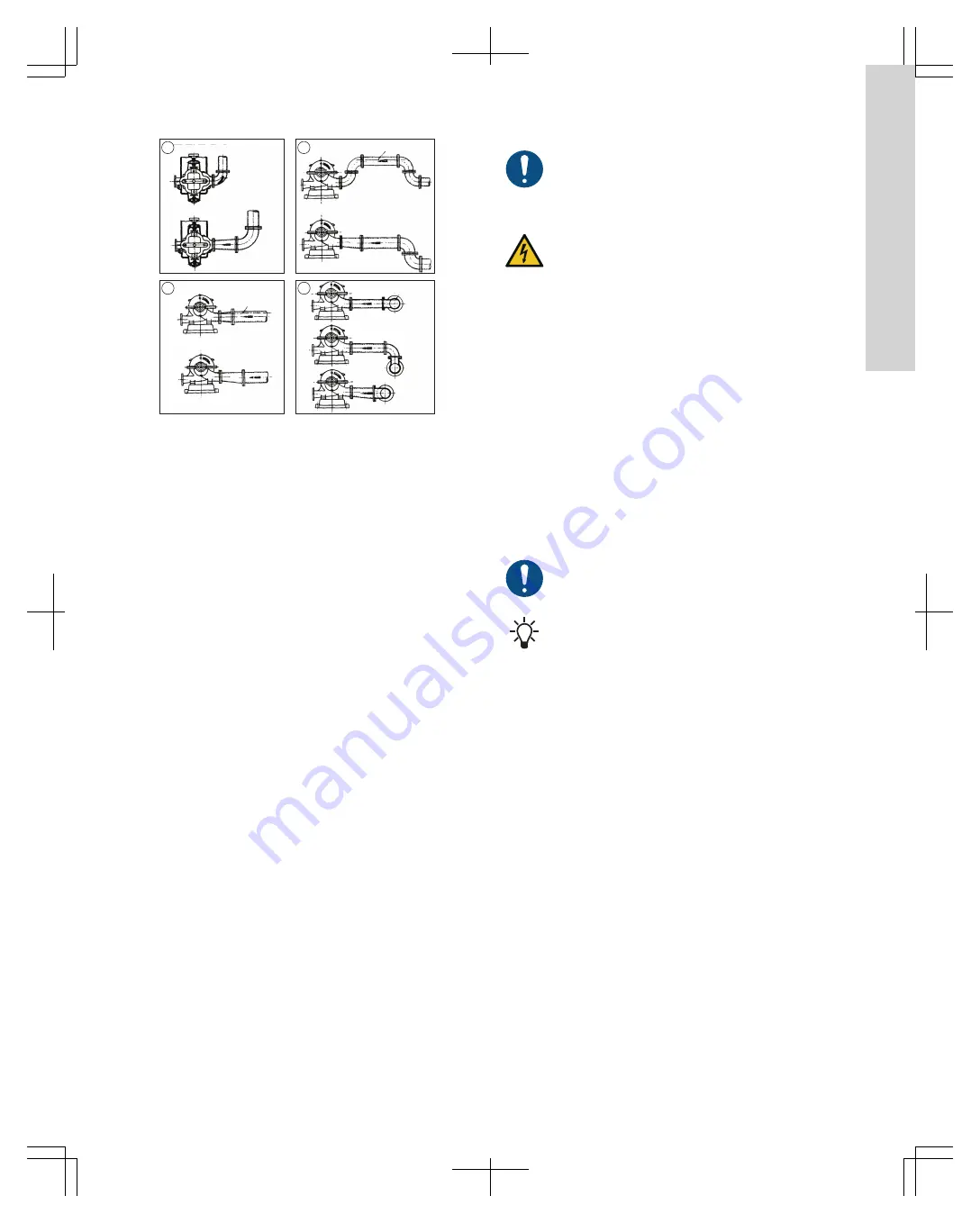

Fig.

Pipe arrangements

4

.6.2

Suction pipes

The inlet and outlet pipes must be of sufficient size and free of

internal foreign material.

Considerations for inlet pipes to achieve optimal performance are:

•

When operating under inlet pressure, pipe may be equal to, but

never less than, the inlet nozzle size.

•

Failure of the inlet pipe to deliver the liquid to the pump in this

condition can lead to noisy operation, swirling of liquid around

the suspended pump assembly, premature bearing failure and

cavitation damage to the impeller and inlet portions of the

casing.

Contact Peerless Pump for further information.

4

.6.3

Inlet valves and manifolds

Install isolation valves on the inlet and outlet pipes so that the pump

can be isolated for maintenance.

4

.6.4

Outlet valves

Install a non-return valve and an isolation valve in the outlet pipe.

The non-return valve protects the pump from backflow and

excessive backpressure. We recommend closing the isolation valve

before stopping or starting the pump.

Pump backspin and hydraulic shock can cause severe damage to

the pump and motor. To prevent this type of damage, install at least

one non-return valve in the outlet pipe, not more than 25 ft (7.5 m)

after the outlet flange.

If increasers are used on the outlet side of the pump to increase the

size of piping, place them between the non-return valve and the

pump.

If expansion joints are used, place them between the pipe anchor

and the non-return valve.

4

.6.5

Nozzle loads

Minimize pump nozzle loads by aligning the pipes with the pump

nozzles. Contact Peerless Pump for allowable nozzle load for your

particular system design.

4

.7

Lubrication, priming and cooling systems

If lubrication, priming and cooling systems are supplied, please see

additional documents attached to the pump or contact Peerless

Pump.

4

.8

Electrical

I

nstallation

All electrical connections must be carried out by a

qualified electrician in accordance with local regulations.

DANGER

Electric shock

Death or serious personal injury

‐

Switch off the power supply before you start any work

on the product.

‐

Make sure that the power supply cannot be switched

on accidentally.

Locate the electrical conduit and boxes so as to avoid obstruction of

the pump.

Check speed versus torque requirements during the starting phase

of a pump against the speed versus torque curve of the driving

motor.

In order to accelerate the pump up to rated speed, the driver should

be capable of supplying more torque at each speed than required

by the pump. In general, this condition is easily attainable with

standard induction or synchronous motors, except under certain

conditions when a motor with high pull-in torque may be required,

such as high specific speed pumps over 5000 US units (100 metric

units) or reduced voltage startup.

To achieve a smooth start for the pumping equipment, consider

connecting autotransformers to the starting panel or using solid-

state starters. These provide a gradual increase in voltage up to

rated voltage ensuring even acceleration.

4

.9

Control, monitoring, and alarm equipment

Check control and alarm systems for correct installation

and function according to the manufacturer's instructions.

Check all alarm point settings.

4

.9.1

Stopping the unit/reverse runaway speed

A sudden power and/or outlet valve failure during pump operation

against a static head will result in a flow reversal, and the pump will

operate as a hydraulic turbine in a direction opposite to that of

normal pump operation.

If the driver offers little resistance while running backwards, the

rotational speed may approach the pump-specific speed.

This condition is called runaway speed and causes mechanical

problems. Contact Peerless Pump for recommendations to prevent

this condition.

5

. Starting up the product

5

.1

Lubricating the pump

Before attempting to start the pump, check the following items:

•

lubrication fitting at packing, if applicable

•

lubrication for pump bearing

•

lubrication of the driver

•

oil-cooling connections for the driver, if applicable

Good practice includes the following:

•

Keep lubricant clean, and use a dust-tight cover on the storage

container.

•

Use the oldest lubricant first.

•

Clean the pump lubricant fittings before re-lubricating with

grease.

•

Use clean dispensing equipment.

1

3

English (US)