11

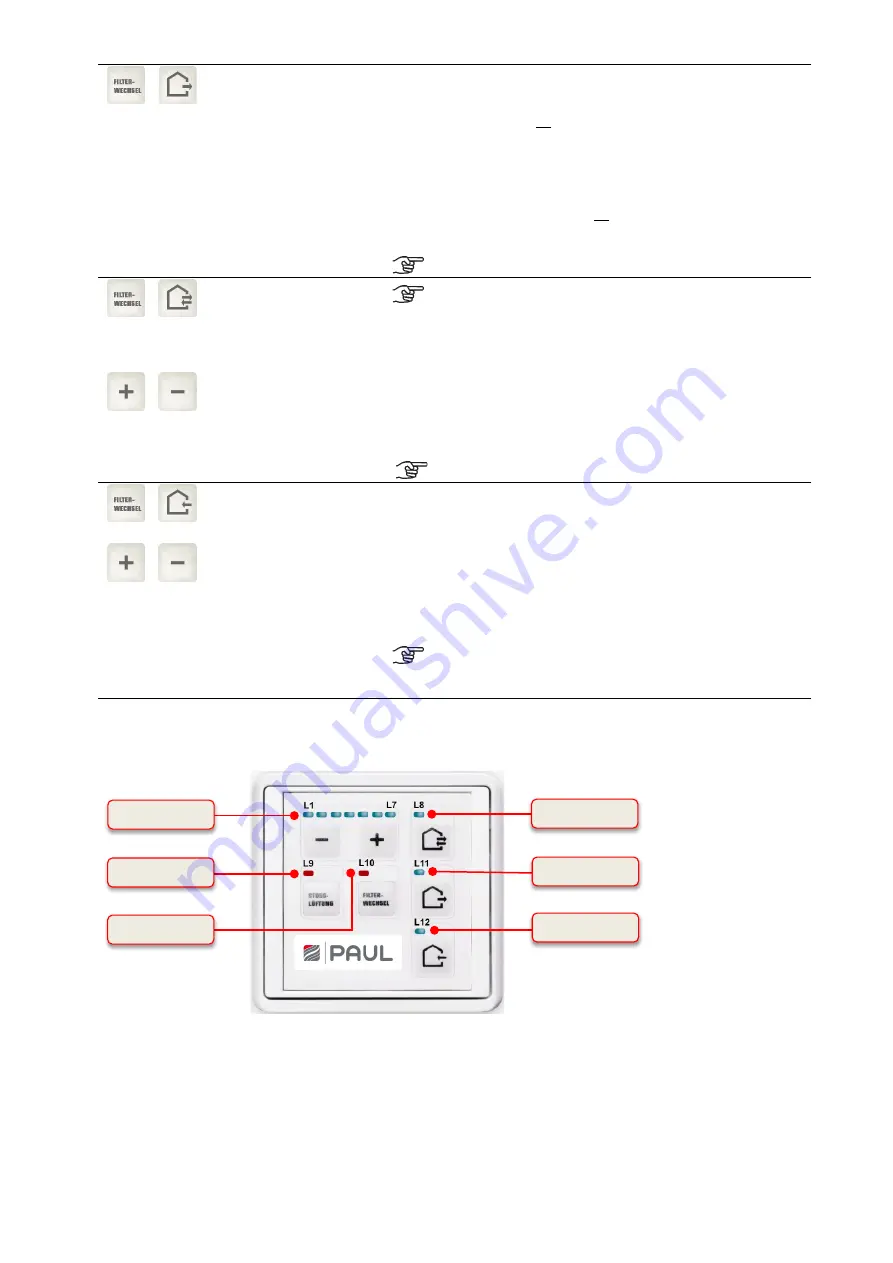

LED L8

LED L11

LED L10

LED L12

LED L9

LED L1 … L7

…

Key combination

configuration mode for

operation together with a

fireplace

Pushing the key combination for at least 3 seconds deactivates the

extract air mode permanently. This status is signalled by LEDs

L8+L11+L12, where L8 and L12 are lit up, L11 blinks 2 times and

then remains switched off. This signal is only visible when holding

the key combination. Activating the extract air mode key in the

deactivated state results in a short 3 time blinking of LED L11 to

signal the deactivated state. Pushing the key combination again for

at least 3 s cancels the key lock. This change is again signalled by

the LEDs L8+L11+L12, where L8 and L12 are lit up, L11 blinks 2

times and then remains switched on. This signal is only visible when

holding the key combination. This enables the extract air mode

again.

Always press the reset filter replacement key first!

…

…

Key combination for the

summer ventilation

temperature limit

configuration mode

Setting keys

The summer ventilation can only be implemented with

an LED control panel if it has been released in the

factory setting.

Pushing the key combination for at least 3 seconds activates the

setting for the temperature limit. This status is signalled by the

blinking of LEDs L8 and L10. With the setting keys the upper

temperature limit for summer ventilation depending on the extract air

temperature can be set between 21 °C (LED L1 lights up) and 27 °C

(LED L7 lights up). After pressing the key combination again for at

least 3 s the setting is saved and the summer ventilation

temperature limit is terminated.

Always press the reset filter replacement key first!

…

…

Key combination

imbalance configuration

mode

Keys

for setting the balance

By pushing the key combination for at least 3s, the imbalance

configuration mode is activated and the LEDs L10 and L12 blink.

The keys for setting the balance can now be used to set the balance

of the fan speeds active upon activation of the imbalance

configuration mode in 5% increments. The balance is not set for

each fan speed individually, but jointly for a group of fan speeds.

The adjustable range is between -

15% (L1) and +15% (L7). In the

central position (L4) the supply air and extract air run with the same

rotational speed. After pressing the key combination again, the

setting is saved and the imbalance configuration mode concluded.

Always press the reset filter replacement key first!

1st

group

fan speeds <1+2>

2nd group

fan speeds < 3 +4+5>

3rd group

fan speeds <6+7>

Table 2: Control functions of the LED control panels

4.2.1.2 Signals used to indicate operating and error conditions

Fig. 3: LED signals LED control panel

Содержание FOCUS 200 Base

Страница 1: ...Translation of the original instruction manual Heat Recovery Unit FOCUS F 200...

Страница 49: ...49 Dimensions Fig 43 Dimensional drawing FOCUS...

Страница 50: ...50 FOCUS circuit plan Fig 44 Terminal assignment circuit diagram FOCUS...

Страница 51: ...51 Master Controller terminal assignment Fig 45 Master Controller terminal assignment...