192-011006N8 PSD1 Installation Guide

192-011006N8 2019-07

09.10.19 09:27

69 (109)

6.1.4.

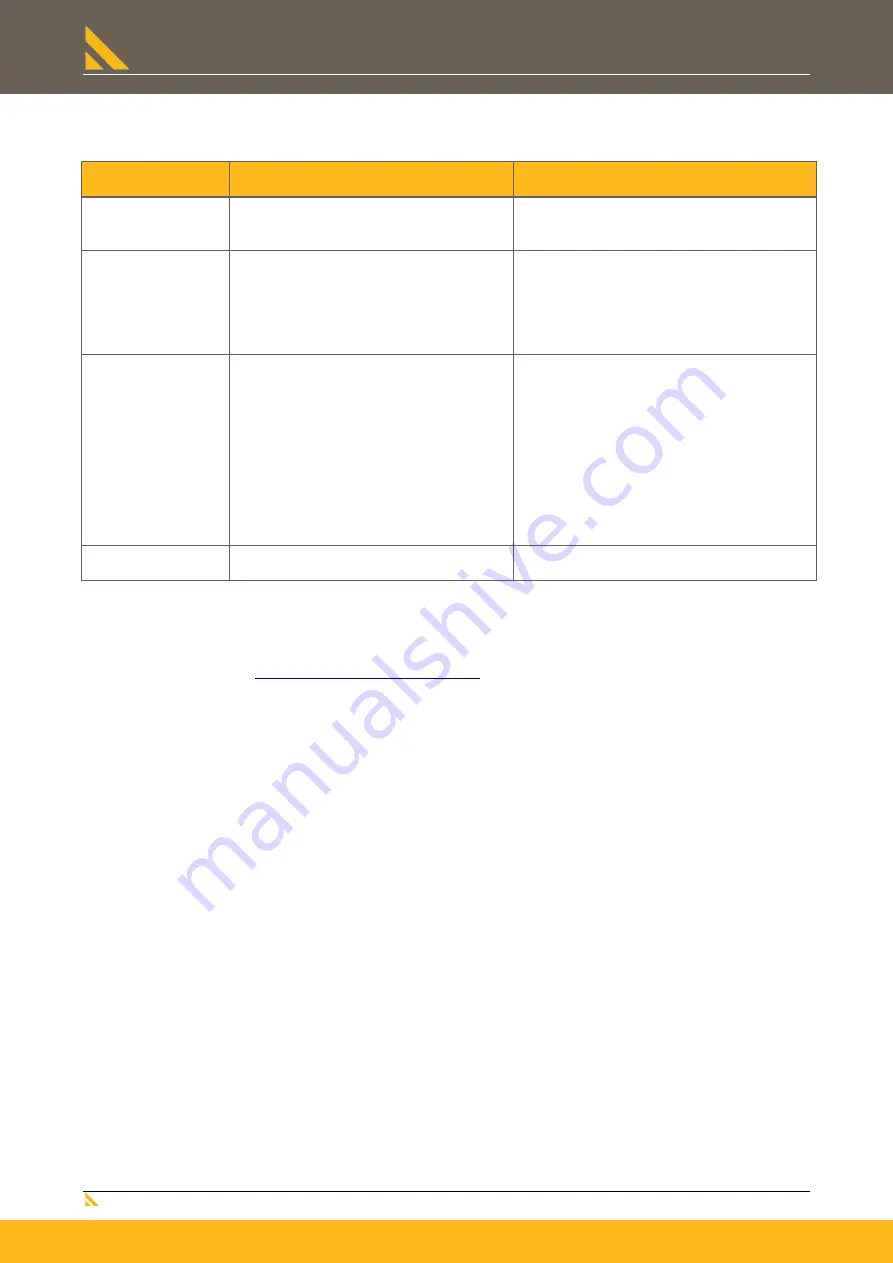

Advantages of using the "safe torque off" safety function" STO

Safety category 3 in accordance with EN ISO 13849-1

Requirements

performance features

Use of the safe torque off function

Conventional solution: Use of external

switching elements

Reduced switching

overhead

Simple wiring, certified application examples

Grouping of drive controllers on a mains

contactor is possible.

Two safety-oriented power contactors in series

connection are required.

Use in the production

process

High operating cycles,

high reliability, low

wear

Extremely high operating cycles thanks to

almost wear-free technology (low-voltage

relay and electronic switch). The "safe torque

off" status is attained due to the use of

wear-free electronic switches (IGBTs).

This performance feature cannot be reached

with conventional technology.

Use in the production

process

High reaction speed,

fast restart

Drive controller remains performance- and

control-oriented in connected state.

No significant waiting times due to restart.

When using power contactors in the supply, a

long waiting time for the energy discharge of the

DC link circuit is required.

When using two power contactors on the motor

side, the reaction times may increase, you must

however take into consideration other

disadvantages:

a) Securing that switching takes only place in

powerless state (Direct current! Constant

electric arcs must be prevented).

b) Increased overhead for EMC conform wiring.

Emergency-stop

function

Allowed

Allowed

6.2

STO Operating Principle

In this chapter you can read about:

•

STO principle with PSD1-S ....................................................................................................... 70

•

STO principle of PSD1-S with one axis module ........................................................................ 70

•

STO principle of PSD1-M with two axis modules ...................................................................... 70

•

STO principle of PSD1-M with three axis modules .................................................................... 71

Principle

The current flow in the motor windings is controlled by a power semiconductor

bridge (6-fold IGBT).

A rotating field is created via the processor by means of the power output stage.

Between control logic and power module, optocouplers are used for potential

separation.

The STO input are on the front panel. 2 optocouplers are controlled via 2 STO

channels (STOA/ & STOB/). At a STO via external safety control both auxiliary

power supplies of the power output stage are switched off via 2 channels. Due to

this fact the power semiconductor bridge is blocked and there is no motor current.

The reset procedure of the Safe Torque Off depends on the configurated settings

of the object STO_Setup.

At standard settings STO_Setup=0 the motor may be powered as soon as STOA/

and STOB/ inputs are reset to high level.

At settings STO_Setup=1 the generated error 0x5492 needs be acknowledged

before the motor can be powered again.

Detection of hardware failure

An internal Hardware monitoring recognizes the failure of the optocoupler by

continuously comparing both channels. If the monitoring system recognizes a

discrepancy for a defined time (approx. 10 s) the fault is stored in the hardware.

This is reported via the error code 0x5493 ?.

The error can only be reset by a hardware reset (switching off and on the servo

drive). But before the error must be found and solved by the user.