No. SX-DSV02829 -

37-

4-2-2 Electronic gear function

The electronic gear is a function which makes the value which multiplies by the electronic gear ratio defined by the

object to the position command from host controller as the position command to a position control section.

By using this function, moving amount of the motor per command can be set to the desired value.

In MINAS-A5BL series, a setup of an electronic gear ratio with a parameter Pr0.09(Numerator of electronic gear

ratio) and Pr0.10(Denominator of electronic gear ratio) has not corresponded, an electronic gear ratio is set up by the

object 608Fh(Position encoder resolution), 6091h(Gear ratio) and 6092h(Feed constant) specified to CoE(CiA402).

The equation below calculates the relationship between the unit (command) defined by the user and internal unit (pulse):

(Note) - Electronic gear ratio is valid only within the range of 1000 times to 1/1000 times.

When the range is exceeded, the value is saturated in the range, and Err88.3 (Improper operation error

protection) occurs.

- When the denominator or numerator exceeds the unsigned 64-bit size in the calculation process of

electronic gear ratio, Err88.3 (Improper operation error protection) occurs.

- When the denominator or numerator exceeds the unsigned 32-bit size in the final calculation result of

electronic gear ratio, Err88.3 (Improper operation error protection) occurs.

- Set the electronic gear ratio with several objects.

An error may become large depending on the combination of settings.

- 608Fh-01h (Encoder increments) is automatically set according to feedback scale resolution.

608Fh-01h (Encoder increments) and 608Fh-02h (Motor revolutions) are automatically set as shown

in the table below in accordance with the feedback scale resolution.

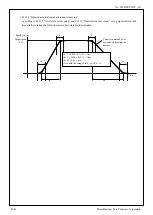

Linear type

Rotary type

608Fh-01h(Encoder increments)

1,000,000

(

fixed

)

Resolution per 1 revolution [p/r] *1)

608Fh-02h(Motor revolutions)

Feedback scale resolution [nm/p] *1)

1

(

fixed

)

*1) The set value of Pr9.01 "Feedback scale resolution/number of scale pulses per revolution" is set

automatically. However, if Err60.0 "Motor setting error protection" occurs, the value may differ

from the set value of Pr9.01.

The default value of 6092h-01h (Feed) is set so that the electronic gear ratio becomes 1:1 when the

linear type feedback scale with resolution of 1 nm/p is used (Pr9.01=1).

When using with the rotary type, or when using a linear type feedback scale with resolution of other

than 1 nm/p, pay attention to the setting of electronic gear ratio.

- In the position information initialization when Init changes to PreOp in the absolute mode, make a

setting so that the value of "Absolute feedback scale position [pulse/unit]/Electronic gear ratio" is in

the range from -2

31

(-2147483648) to +2

31

-1 (2147483647).

Operations out of this range are not guaranteed.

Check the operation range of the absolute feedback scale position and the electronic gear ratio.

- The unit of the movement amount setting of the test run function by the setup support tool

PANATERM is [pulse], not [command unit], so care should be taken.

For details, refer to Technical Reference, SX-DSV02830”Section 6-9-4 2”, EtherCAT communication specification.

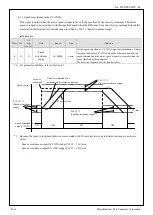

Position demand value × Electronic gear ratio

=

Position demand internal value

Feed constant

Position encoder resolution × Gear ratio

Electronic gear ratio =

R1.00

Motor Business Unit, Panasonic Corporation