Page 45

TU2506

ǀ

TU2807V

US

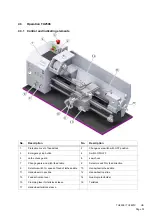

4.12

Immobilising the lathe saddle

The cutting force produced dur-

ing facing, recessing or slicing

process may displace the lathe

saddle.

Secure the lathe saddle

using the tightening screw.

Fig.4-15:

Lathe saddle TU2506

Fig.4-16:

Lathe saddle TU2807V

4.12.1 Turning tapers with the top slide

See also

"Turning Speeds & Feeds“ on page 48

It is possible to turn short tapers with the top slide. The scaling takes place to 60° degree of

angle. Adjusting of the top slide over the 60° angle mark outside is possible.

Loosen the two nuts on the left and the right of the top slide.

Swivel the top slide.

Clamp the top slide again.

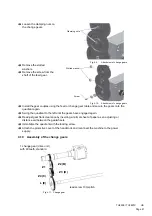

4.12.2 Cross-adjustment of the tailstock

See also

"Turning Speeds & Feeds“ on page 48

The cross-adjustment of the tailstock is used for turning long, thin shafts.

Loosen the locking handle of the tailstock.

Unscrew the locking screw approximately half a turn.

By alternately loosening and tightening the two (front and rear) adjusting screws, the tailstock is moved

out of the central position. The desired cross-adjustment can be read off the scale.

First retighten the locking handle and then the two (front and rear) adjusting screws.

ATTENTION!

Check clamping of the tailstock and the quill, respectively, for turning jobs between

centres! Fit the securing screw at the end of the lathe bed in order to prevent the

tailstock from falling off the lathe bed.

tightening screw

tightening screw

Содержание TU 2506

Страница 1: ...US Item No 9684509 Operating manual Version 2 2 2 Lathe...

Страница 28: ...Page 28 TU2506 TU2807V US 3 7 2 Chuck flange TU2506 TU2807V Fig 3 1 Chuck flange TU2506 TU2807V Unit mm...

Страница 74: ...Page 74 TU2506 US...

Страница 92: ...Page 92 TU2506 TU2807V US 8 Wiring diagrams 8 1 TU2506 Fig 8 1 Wiring diagram TU2506...

Страница 93: ...Page 93 TU2506 TU2807V US 8 2 TU2807V 230V Fig 8 2 Wiring diagram TU2807V...

Страница 98: ...Page 98 TU2506 TU2807V US...