38

1. Drain and refill the feed tank with 10 to 40 L/m

2

(1 to 4 L/ft

2

) buffer or WFI.

2. Open the retentate and permeate valves.

3. Adjust the pump to deliver a flow rate of 5 to 10 L/min/m

2

(0.5 to 1 L/min/ft

2

). Do

not exceed a feed pressure of 2 barg (30 psig). If necessary, restrict the permeate

valve, so at least 50% of flow is removed from the retentate line.

4. Pass a minimum of 15 to 20 L/m

2

(1.5 to 2 L/ft

2

) through the retentate line to

waste.

5. Stop the pump.

5.1.2

Flush the Permeate Line to Waste

1. Close the retentate valve. Open the permeate valve.

2. Adjust the pump to deliver a permeate flow rate of 5 L/min/m

2

(0.5 L/min/ft

2

) or

until the feed pressure equals 2 barg (30 psig).

3. Pass 15 to 20 L/m

2

(1.5 to 2 L/ft

2

) through the permeate.

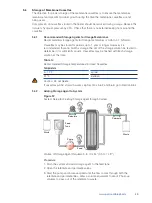

5.2

Cleaning Cassettes

Volume Required:

5 L/m

2

(0.5 L/ft

2

) minimum

Recommended cleaning agents for Pall membranes (see Section 6.2):

Membrane Types: Omega

Cleaning Solutions: 0.1 to 0.5 N NaOH at 25 to 45 °C

0.1 to 0.5 N NaOH + 200 to 400 ppm NaOCl at 25 to 45 °C

Warning: Many solutions that are recommended for cleaning may be corrosive. Ensure proper

safety procedures are followed while handling, mixing and preparing these reagents.

5.2.1

Adding Cleaning Agent to System

1. Drain the system and feed tank.

2. Fill the feed tank with 15 to 20 L/m

2

(1.5 to 2 L/ft

2

) of cleaning solution.

3. Open the permeate and retentate valves.

4. With the retentate and permeate line still directed to waste, start the pump and

run a small volume of cleaning solution through the system to waste.

Typically flushing with one or two system hold-up volumes is sufficient. It may be

necessary to partially close the retentate valve to force liquid through the permeate.

5. Stop the pump.

6. Return the retentate and permeate line back to the feed tank.