ILK

22/33/44/55/66

I

NSTALLATION

M

ANUAL

Revision 1.6

- 23 -

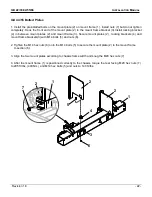

5.4

Platform Installation

•

If power pack is still removed from mount tube for welding, reconnect the ground cable and pow-

er connection. Do not push back in, welding is not finished!!!!!!

Attention: check all PC-Board connections for tightness

5.4.1

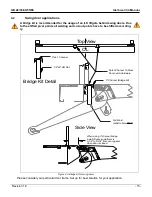

Attach platform to liftarm

1. Remove pins attached to mounting fixture and lift arm.

Lift arm will drop about 12”- 16”.

2. Remove mounting fixture form truck bed.

3. Lower lift arm to ground to bleed air out.

4. Support platform horizontally with forklift, overhead crane or similar equipment.

5. Install platform onto lift arm using small pins.

6. Tighten up pin lock bolts.

5.4.2

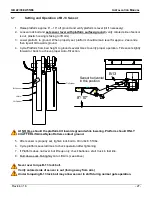

Installation and Adjusting the tilt cylinders

Pin only one cylinder at a time to the platform

1. Tilt platform up to a point of easy access of the tilt bushings (using the forklift, overhead crane, etc.)

2. When installing the tilt cylinder into the platform, extend the tilting cylinder by pressing the switch for

opening and closing until the pins fit in the tilt cylinder and the platform bushings. For this purpose,

hold the platform sensor B-15 with the cable straight down.

3. For the platform to be in the required end position, the

tilting cylinder must be

fully extended

4. Verify that reservoir breather cap is installed and hydraulic fluid is at proper level with platform on the

ground

Make sure to tighten the tilt piston rod lock nuts when you are finished.

Ideal position:

45 degrees