OUMAN OY

www.ouman.fi

2.

3.

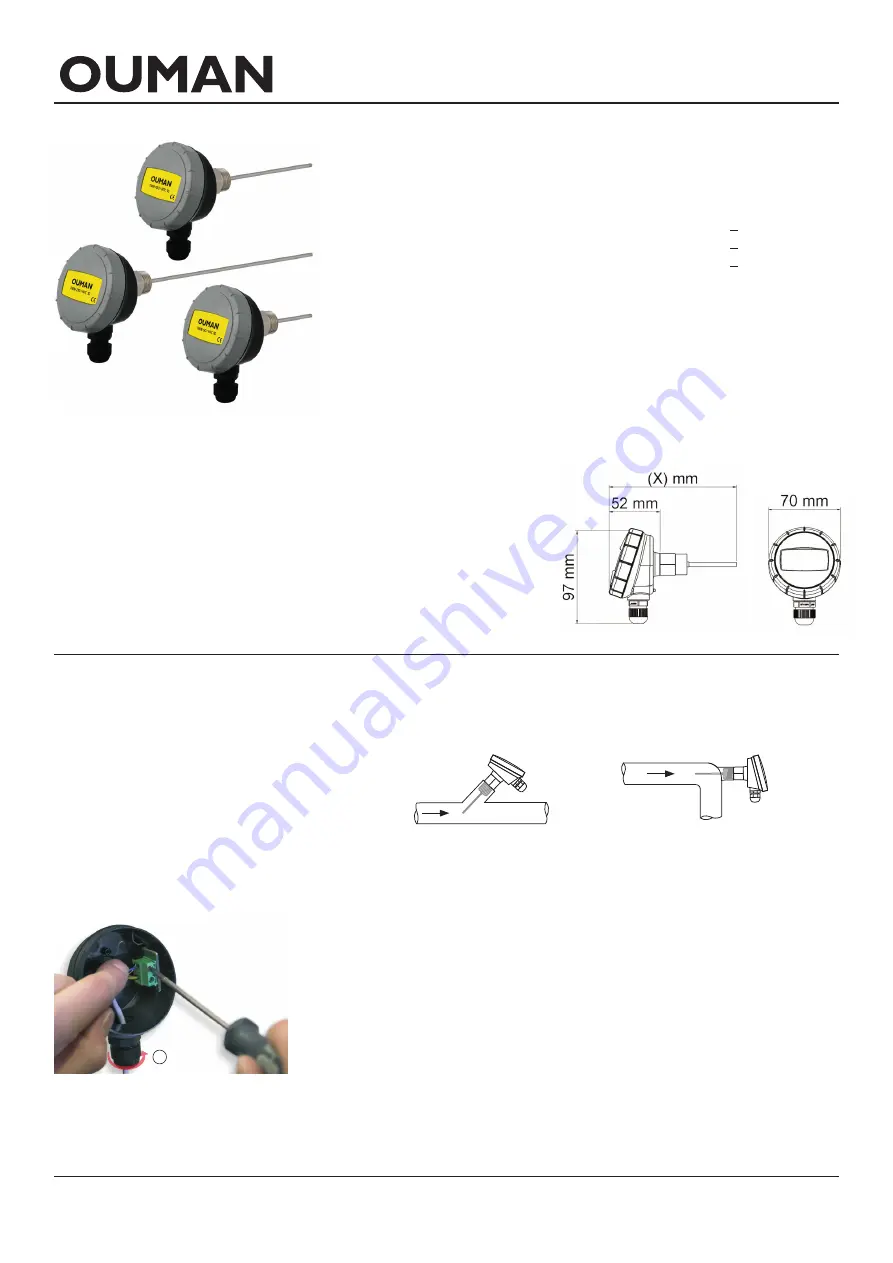

X = 130 mm, 180 mm, 290 mm

TMW

Water sensor

The water sensors (TMW) installed on the water pipes are suitable for heat-

ing and domestic hot water control. The water sensors come with immersion

sensor of different lenghts as follows (Ø 4 mm):

The sensor should be positioned at a point where the water is well mixed.

With heating control install the supply water sensor approx. 1 m from the

mixing point and with hot water temperature control install the supply water

sensor less than 0,5 m from the mixing point

Installation and connection

Install the water sensor on the bend of the water-supply pipe so that the

immersion sensor faces opposite the direciton of flow.

1. Screw the sensor on a welded pipe fitting or T-piece using proper sealing

methods. The case can be turned clockwise at the end of the rst pocket

until the cable’s bushing seal goes down.

2. Open the screw-off lid and connect the sensor to the controlling device as

a two-wire connection using weak current cable. The polarity of the cable

is irrelevant.

3. Tighten the bushing seal so that it acts as a seal and repels water.

Type code

Meas. element

Meas. accuracy

TMW-(50, 100, 210) / NTC10

NTC 10

+ 0,2 °C (0-70 °C)

TMW-(50, 100, 210) / Pt1000

Pt 1000

+ 1 °C (0-70 °C)

TMW-(50, 100, 210) / Ni1000

Ni 1000 LG

+ 1 °C (0-70 °C)

Technical information

Materials

- Case

Cover PC, base PBT, seal PA

- Immersion pipe and nipple

RST AISI 304 EN 1.4301

Range of use

-50 °C...+130 °C (water, cooling liquids)

Protection class

IP 54

Seal

M16 x 1,5

Pressure class

PN 16

Time constant

< 3 s

Thread

R ½”, cross-knurling

Wrench size

22 mm

Dimensions: