New bearing: 40 mm inside diameter, 44mm outside diameter.

Defect bearing: ≥ 42,2 mm inside diameter.

Measure the diameter several places to get the correct impression of the bearing ovality.

Large type, 50 mm

New bearing: 50 mm inside diameter, 55 mm outside diameter

Defect bearing: ≥ 52,7 mm inside diameter.

Measure the diameter several places to get the correct impression of the bearing ovality. The material

thickness in bearings must under no circumstances be ≤ 0,2 mm. If so, the bearing is defect and must be

replaced immediately. The reason is to avoid serious damage to the rollers axle, and potential mechanical

breakdown.

Figure 7.32 :

Example picture of plain bearing. New bearing to the left, and worn out/defect

bearing to the right.

NOTE: Good practice is to change the bearings before reaching the maximum degree of wear.

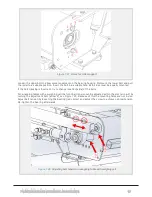

7.12.3 Remove sprockets

The sprockets are fastened to the axle with an eccentric connection. Follow this procedure to loosen the

sprockets.

1. Make an indication mark across both the sprocket and axle (red line) that indicates movement

between the axle and the sprocket.

2. Set a solid steel bar on one of the sprocket teeth, and hit it with a hammer (opposite of the

sprocket working direction).

3. Remove the sprocket, when the indication mark has shifted.

7 MAINTENANCE AND MECHANICAL ADJUSTMENTS

90

Содержание Dens-X Compactor

Страница 14: ...1 6 DECLARATION OF CONFORMITY 1 GENERAL 14...

Страница 102: ...8 6 4 Gearbox and gears for hydraulic motors Gear oil Renolin unisyn CLP 220N 8 LUBRICATION 102...

Страница 103: ...8 7 MANUAL LUBRICATION CHARTS 8 7 1 The compactor 8 LUBRICATION 103...

Страница 104: ...8 7 2 Feed hopper F25 8 LUBRICATION 104...

Страница 105: ...8 7 3 Flexible drawbar 8 LUBRICATION 105...

Страница 109: ...10 1 MAIN POWER SUPPLY E STOP SWITCHES AND ELECTRICAL CABINET 10 ELECTRICS 109...

Страница 110: ...10 2 ELECTRICAL CABINET POWER SUPPLY RAIL 10 ELECTRICS 110...

Страница 111: ...10 3 SENSORS AND MANUAL CONTROLS 10 ELECTRICS 111...

Страница 112: ...10 4 VALVES FAN MOTORS AND PUMPS 10 ELECTRICS 112...

Страница 124: ...10 9 SENSOR OVERVIEW 10 ELECTRICS 124...

Страница 128: ...11 1 1 Complete diagram 11 HYDRAULICS 128...

Страница 129: ...11 1 2 Wrapping table chamber and elevator control 11 HYDRAULICS 129...

Страница 130: ...11 1 3 Plastic tying unit sub conveyor and feed hopper 11 HYDRAULICS 130...

Страница 131: ...11 1 4 Additional feed hopper control for F25 and chamber drive 11 HYDRAULICS 131...

Страница 133: ...11 2 VALVE OVERVIEW 11 2 1 Valve chart for Dens X 11 HYDRAULICS 133...

Страница 137: ...12 6 3 Dimensional sketch F25 operating mode 12 SPECIFICATIONS 137...

Страница 138: ...12 6 4 Dimensional sketch F25 transport mode 12 SPECIFICATIONS 138...

Страница 142: ...M Maintenance 13 69 71 INDEX 142...