5

Nominal size, tightening torque, and installation method

Type

Motor

frame size

[mm (in.)]

Screw

size

Tightening

torque

[N·m (oz-in)]

Effective depth

of screw thread

[mm (in.)]

Installation

method

Standard

20 (0.79)

M2

0.25 (35)

2.5 (0.098)

A

28 (1.10)

M2.5

0.5 (71)

2.5 (0.098)

42 (1.65)

M3

1 (142)

4.5 (0.177)

60 (2.36)

M4

2 (280)

−

B

85 (3.35)

M6

3 (420)

TH

geared

28 (1.10)

M2.5

0.5 (71)

4 (0.157)

A

42 (1.65)

60 (2.36)

M4

2 (280)

8 (0.315)

90 (3.54)

M8

4 (560)

15 (0.591)

FC

geared

42 (1.65)

M4

2 (280)

−

B

60 (2.36)

M5

2.5 (350)

PL

geared

PS

geared

PN

geared

Harmonic

geared *1

28 (1.10)

M3

1 (142)

6 (0.24)

A

42 (1.65)

M4

2 (280)

8 (0.315)

60 (2.36)

M5

2.5 (350)

10 (0.394)

90 (3.54)

M8

4 (560)

15 (0.591)

Harmonic

geared *2

90 (3.54)

M8

4 (560)

−

B

*1

ARM24

,

ARM46

, and

ARM66

only.

*2

ARM98

only.

Installing a load

When installing a load to the motor, align the centers of the motor output

shaft and load shaft. Be careful not to damage the output shaft or the

bearings (ball bearings) when installing a coupling or pulley to the motor

output shaft.

z

Electromagnetic brake motor

To release the electromagnetic brake and install the load, a DC power

supply is needed to power the electromagnetic brake. Use a cable for

electromagnetic brake to connect a DC power supply of 24 VDC to the motor.

Black

White

Varistor *3

Switch

24 VDC±5% *2

Cable for electromagnetic

brake

Electromagnetic brake motor

DC power supply for

electromagnetic brake *1

*1 The power supply current capacities are as follows.

ARM24

,

ARM26

: 0.05 A or more

ARM46

: 0.08 A or more

ARM66

,

ARM69

,

ARM98

: 0.25 A or more

*2 If the distance between the motor and driver is extended to 20 m (65.6 ft.) to

30 m (98.4 ft.), use a power supply of 24 VDC±4%.

*3 Provide a varistor to protect the contact of the switch or to prevent electrical

noise. It is included with the electromagnetic brake motor of DC power input

type.

[Recommended varistor: Z15D121 (SEMITEC Corporation)].

z

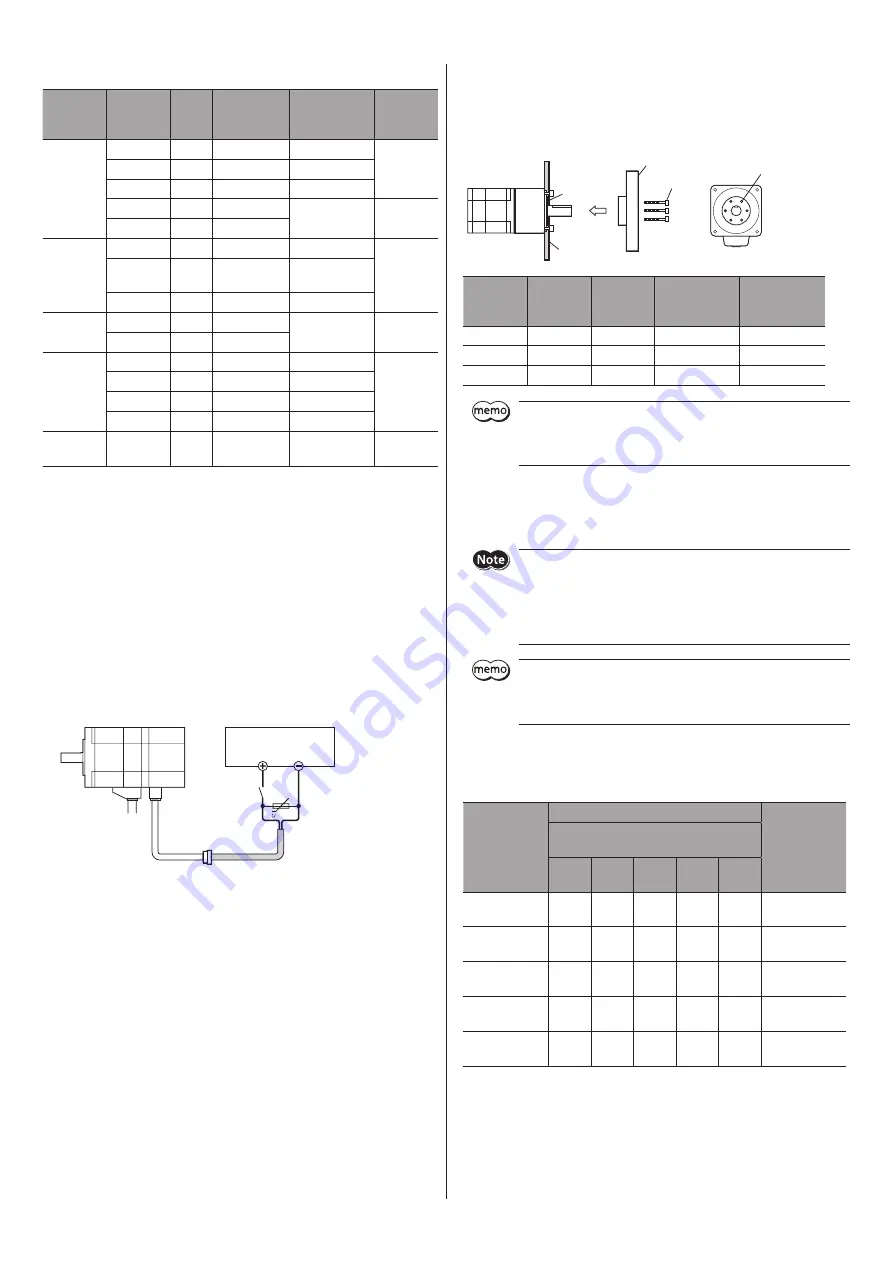

Installing on the flange surface (Harmonic geared type)

With a Harmonic geared type (excluding

ARM98

), a load can be installed

directly to the gear using the load mounting holes provided on the flange

surface.

Metal plate

Frange

Screws

Load

Load mounting

holes

Motor

model

Screw size

Number of

screw

Tightening

torque

[N·m (oz-in)]

Effective depth

of screw thread

[mm (in.)]

ARM24

M3

4

1.4 (198)

4 (0.157)

ARM46

M3

6

1.4 (198)

5 (0.2)

ARM66

M4

6

2.5 (350)

6 (0.24)

y

When installing a load on the flange surface, the load cannot be

mounted using the key slot in the output shaft.

y

Design an appropriate installation layout so that the load will not

contact the metal plate or screws used for installing the motor.

Permissible radial load, permissible axial load, and

permissible moment load

y

If the radial load or axial load exceeds the specified allowable value,

repeated load applications may cause the bearing (ball bearings) or

output shaft of the motor to undergo a fatigue failure.

y

With a double shaft type, do not apply load torque, radial load, or

axial load to the output shaft on the opposite side of the motor

output shaft.

The permissible radial load and permissible axial load of the

PS

geared

type and

PN

geared type represent the value that the service life of

the gear part satisfies 20,000 hours when either of the radial load or

axial load is applied to the gear output shaft.

z

Permissible radial load, permissible axial load

•

Standard type

Motor model

Permissible radial load [N (lb.)]

Permissible axial

load [N (lb.)]

Distance from the tip of motor output shaft

[mm (in.)]

0

(0)

5

(0.2)

10

(0.39)

15

(0.59)

20

(0.79)

ARM14

ARM15

12

(2.7)

15

(3.3)

−

−

−

3 (0.67)

ARM24

ARM26

25

(5.6)

34

(7.6)

52

(11.7)

−

−

5 (1.12)

ARM46

35

(7.8)

44

(9.9)

58

(13)

85

(19.1)

−

15 (3.3)

ARM66

ARM69

90

(20)

100

(22)

130

(29)

180

(40)

270

(60)

30 (6.7)

ARM98

ARM911

260

(58)

290

(65)

340

(76)

390

(87)

480

(108)

60 (13.5)