5238-E P-62

SECTION 6 OFFSET FUNCTION

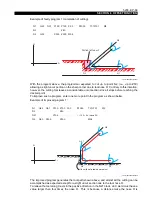

(1) To obtain point N2’ when the center of the tool nose R is at point N1’, proceed as follows:

•

Draw a straight line parallel to the direction of tool advance, N1 - N2, offset in the specified

direction, (to the right since G42 is specified), by the tool nose radius compensation

amount. This yields the straight line passing N1’ and N2’.

•

Draw a straight line parallel to the direction of tool advance, N2 - N3, offset in the specified

direction, (to the right of or above N2 - N3 since G42 dominates the compensation mode)

by the tool nose radius compensation amount. This yields the straight line passing N2’ and

N3’.

•

The nose R center for the commanded point N2’ is the point of intersection of these two

straight lines.

The center of the tool nose radius advances from point N1’ to N2’.

(2) To obtain point N3’:

•

Draw a straight line parallel to the direction of tool advance, N2 - N3, offset in the specified

direction, (to the right of or above N2 - N3 since G42 dominates the compensation mode),

by the tool nose radius compensation amount. This yields the straight line passing N2’ and

N3’.

•

Draw a straight line parallel to the direction of tool advance, N3 - N4, offset in the specified

direction, (to the left since G41 is specified), by the tool nose radius compensation amount.

This yields the straight line passing N3’ and N4’.

•

The nose R center for commanded point N3 is the point of intersection of these two straight

lines.

The center of the tool nose radius advances from point N2’ to point N3’.

(3) To obtain point N4’:

Follow the same procedure indicated above using points N3, N4 and N5.

1-8.

Tool Nose Radius Compensation Programming

1-8-1. G41 and G42

The G41 and G42 codes are used to call out the tool nose radius compensation mode. Since the

uses of these G codes are often confused in programming a part, this section deals with their

particular differences.

G41 : This tool nose radius compensation code is used when the cutting tool moves on the left

side of the workpiece in relation to its direction of advance.

G42 : This tool nose radius compensation code is used when the cutting tool moves on the right

side of the workpiece in terms of its direction of advance.