7.CHECKING THE EQUIPMENT STATUS WITH TopAccess

Error Codes 109

7 CHECKING THE EQUIPMENT STATUS WITH TopAccess

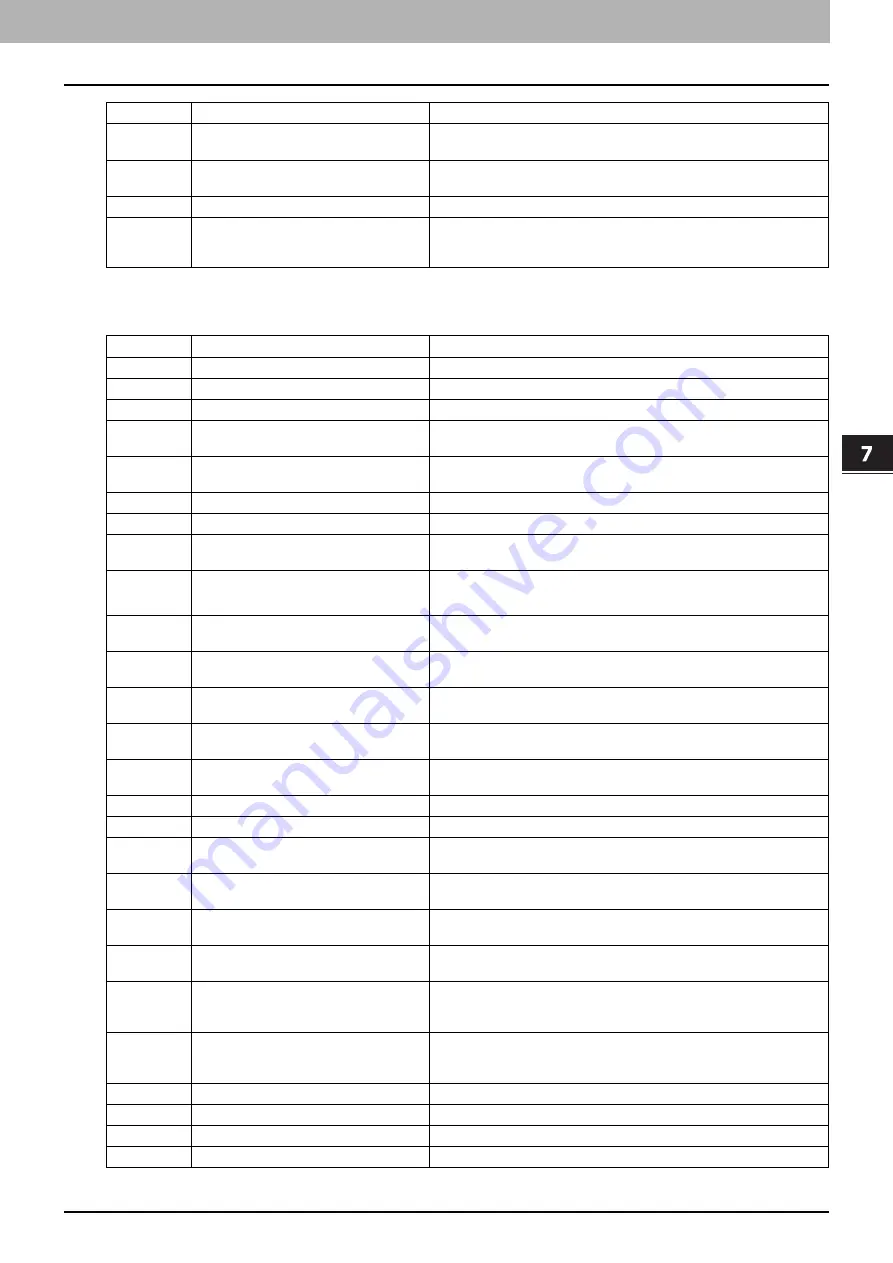

Error codes on transmission and reception

4612

Font download failure

Since there is no space in HDD, the font cannot be registered. Delete at

least one font.

4613

Font download failure

Since an error has occurred, the font cannot be registered. Perform

downloading again or regenerate the font data first.

4621

Downloaded font deletion failure

Check if the font to be deleted is registered.

4F10

Print failure

If the error still persists after reattempting, turn the power OFF and then

back ON. Then make another effort. If the error still persists, contact your

service representative.

Error Code

Problem Description

Corrective Action

Error Code

Problem Description

Corrective Action

0012

Original misfeed

Remove the misfed original.

0013

Door open

Firmly close the open door.

0020

Power interruption

Check the power interruption report.

0030

Interruption by paper misfeeds during

direct transmission

Remove the misfed paper and reattempt the transmission.

0033

Polling Error

Check polling options setup (Security Code, etc.), and check whether the

polling document exists.

0042

Memory full

Make sure that there is sufficient memory before making the call again.

0050

Line busy

Reattempt the communications.

0053

Security Mismatch in Relay or Mail Box

transmission

Confirm the remote party’s Security Code, system password and your

setup.

00B0-00B5

00C0-00C4

00D0-00D2

Signal Error or Line Condition Error

Reattempt the communications.

00E8

HDD error

Reattempt the communications. If the error still persists, contact your

service representative.

00F0

Software failure

Reattempt the communications. If the error still persists, contact your

service representative.

00F1

Hardware noise

Reattempt the communications. If the error still persists, contact your

service representative.

1C10

System access abnormality

Turn the power OFF and then back ON. Perform the problem job again. If

the error still persists, contact your service representative.

1C11

Insufficient memory

Complete any running jobs first before performing the job in error. If the

error still persists, turn the power OFF and then back ON, and try again.

1C12

Message reception error

Turn the power OFF and then back ON. Perform the job in error again.

1C13

Message transmission error

Turn the power OFF and then back ON. Perform the job in error again.

1C14

Invalid parameter

If a template is being used, create it again. If the error still persists, turn

the power OFF and then back ON, and try again.

1C15

Exceeding file capacity

Ask your administrator to change the “Fragment Page Size” setting for

the Internet Fax setting, or reduce the number of pages and try again.

1C30-1C33

Disk access error

Complete any running jobs first before performing the job in error. If the

error still persists, turn the power OFF and then back ON, and try again.

1C40

Image conversion abnormality

Turn the power OFF and then back ON. Perform the job in error again. If

the error still persists, contact your service representative.

1C60

Failed to process your job. Insufficient

Storage space.

Reduce the number of pages of the job in error and perform it again.

Check whether the server or local disk has sufficient space in its disk

capacity.

1C61

Address Book reading failure

Turn the power OFF and then back ON. Perform the job in error again.

Reset the data in the Address Book and perform the job again. If the error

still persists, contact your service representative.

1C63

Terminal IP address unset

Ask your administrator to set the IP address of the equipment.

1C64

Terminal mail address unset

Ask your administrator to set the Email address of the equipment.

1C65

SMTP address unset

Ask your administrator to set the SMTP server address.

1C66

Server time-out error

Check whether the SMTP server is operating properly.

Содержание ES9465

Страница 1: ...MULTIFUNCTIONAL DIGITAL COLOR SYSTEMS Troubleshooting Guide ES9465 MFP ES9475 MFP...

Страница 4: ......

Страница 8: ...6 CONTENTS...

Страница 72: ......

Страница 76: ......

Страница 86: ......

Страница 104: ......

Страница 125: ...ES9465 MFP ES9475 MFP...

Страница 126: ...www okiprintingsolutions com Oki Data Corporation 4 11 22 Shibaura Minato ku Tokyo 108 8551 Japan 45686026EE...