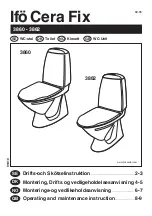

This toilet may be supplied in the standard and large bowl versions and is equipped with a new conceiving of

manual toilet pump offering thefollowing qualities:

• Thanks to the proper button hole-shaped fixing holes on the base, it is possible to replace the toilet without

having to bore new holes (easy substitution with toilets by Jabsco, RM 69 TMC and many others) to do so.

• All mouldings are made of a kind of plastic material fully resistant against uric acids as well as against the

chemical agents contained in the detergents which are normally employed to keep the toilet clean.

• The complete opening from top of the piston allows a quick cleansing without disassembling the toilet from

the base.

• The toilet may be mounted both above and below the waterline. The pump is a self-priming one.

• The reversible left- handed pump mounting enables to install the toilet indifferently on both sides.

• Waste discharge is possible both overboard and into holding tanks on board.

• The toilet is equipped with luxury baked enamel painted wooden seat and cover

OPERATING INSTRUCTIONS

INTRODUCTION: The toilet is one of the most employed equipment on your boat. A correct operation of the toilet is essential

for the safety and the comfort of your crew and your craft. HAZARD RISK: ACCIDENTAL DAMAGE : If the

toilet is connected to any through-hull fittings and if either the toilet or the pipework is damaged, water may

flood in, causing the craft to sink, which may result in loss of life. Therefore, after each usage, both seacocks

(or secondary valves) must be shut. Whenever your craft is unattended, even if only for a very short period of

time, both seacocks (even if secondary valves are fitted) must be shut. - Ensure that all users understand how

to operate the toilet system correctly and safely, including seacocks or secondary valves. - Take special care

to instruct children, the elderly and the visitors. ABSOLUTELY SHUT SEACOCKS!

1. FIRST USE: After periods without use, the toilet may benefit from lubrication. - Open inlet and outlet sea-

cocks (as well as secondary valves, if any) - Half-fill the bowl with warm fresh water containing a few drops

of vegetable oil or baby oil - Keeping the flush control lever in the “Shut position“, pump out the warm water

2. NORMAL USE Open inlet and outlet seacocks (and secondary valves if fitted) - Before use, ensure that

there is enough water in the bowl to prevent the toilet paper from becoming compacted at the bottom of the

bowl If the bowl is empty, move the flush control lever to the “Open” position and pump the handle up and

down, until the flushing pump is primed and water enters the bowl Then, shut the flush control. - Operate

the pump with long, smooth strokes for efficient and easy operation - During use, pump as necessary as to

keep the contents of the bowl low enough for comfort. - Use good quality hard or soft household toilet paper,

but do not use more than necessary. After use, keep the flush control shut and pump until the bowl is empty

When the bowl is empty, open the flush control again and continue to pump until all waste has either left the

boat, or has reached the holding tank (allow 7 complete up and down strokes per metre length of discharge

pipework. Afterwards, shut the flush control and pump until the bowl is empty. Always leave the bowl empty

to minimise odour and spillage. AFTER USE:- SHUT THE FLUSH CONTROL - CLOSE BOTH SEACOCKS

Manual Toilets 2k

2. SERVICING: seal replacement. If water begins to leak round the piston rod on top of the pump, it means

that the seal assembly is worn out and should be replaced. To this purpose, you will have to act as follows:

- You will need a service kit - Raise the handle to the top of its travel and wrap one turn of tape around the

piston rod immediately below the handle. Using pliers, grip the piston rod only through the tape, unscrew the

handle and remove the bumper washer. KEEP HOLD OF THE PISTON ROD AS LONG AS THE OPERATION

HAS BEEN COMPLETED, since if you let it go, it might fall inside the pump. - Unscrew the seal assembly and

slide it off the piston. Wrap one turn of tape around the thread at the top of the piston rod to protect the new

seal, slide the new seal down the piston rod and tighten it. Remove the tape from the thread. Replace the

bumper washer and the handle, absolutely by gripping the piston rod through the tape. Then remove the tape

from the piston rod.,

3. SERVICING: Winterization. Drain the complete system both as a protection against frost damage and to

avoid the growth in the pipework of bacteria that could cause unpleasant smells. Warning: THE USE OF AN-

TI-FREEZE IS NOT RECOMMENDED, as it is not possible to ensure that the product penetrates the whole toilet

system. If, for any reason, an anti-freeze compound is employed. it will have to be a glycol-based one. - open

any secondary valve - remove the base drain plug - Loosen hose clips and disconnect all the hose ends from

the seacock hose tails, the hose toilet tails, and any secondary valves Pump the handle to drain the toilet pump

and ensure that all water is properly drained from the toilet system

HAZARD RISK: SEACOCKS OPENED BY MISTAKE. In case you leave the toilet disassembled and if the

seacocks are opened when the boat is afloat, water will flood in by causing the sinking of the boat and the

possible loss of life. Therefore, it is indispensable to attach a warning notice to the seacocks and, if possible,

wire the seacocks shut. REMEMBER TO ATTACH WARNING NOTICES! If you are not disassembling the toilet:

- reconnect all hose ends and secure them with their hose clips - firmly replace the base drain plug

- fasten down seat, lip and pump handle to prevent any use, and attach a warning notice

4. SERVICING: Overhaul. You will need a service kit containing all wearing parts - refer to the list of parts

for further details. Caution: FOR THE SAFETY OF YOUR CRAFT AND YOUR CREW, USE ONLY GENUINE

SPARE PARTS. Remove the pump assembly as follows: - loosen hose clips, disconnect the inlet hose and the link

hose from the top of the pump - remove the 2 screws which secure the discharge flange to the pump cylinder

- remove the 4 screws which secure the pump cylinder to the base - lift off the pump assembly and pick up the

bottom valve gasket and the joker valve- Dismantle the Pump assembly as follows: - remove the 6 screws that

secure the valve cover - open the flush control before lifting off the valve cover assembly and picking up the

top valve gasket and the valve seat Reassemble the pump as follows:

- Push on the new piston O-ring - Follow the servicing for seal replacement and fit the new seal assembly, the

piston assembly and the handle - Lubricate pump cylinder bore with Vaseline - Locate the valve seat on cylinder

top, locate the top valve gasket on its pegs on the cylinder top and open the flush control before refitting the

valve cover Refit Pump assembly on the toilet as follows:

- Locate the bottom valve gasket on its pegs on the base and locate the joker valve in the discharge elbow -

Secure the discharge flange to the pump cylinder before securing the cylinder to the base

- Examine all hoses throughout their length for chafe, kinks and splits under hose clips, check all hose clips for

corrosion and replace worn out or damaged parts Reconnect all hose ends and secure them with their hose

clips Ensure that the base drain plug is securely placed

TOILET BELOW THE WATERLINE PIC 3 TOILET ABOVE 3 THE WATERLINE PIC 4

IMPORTANTE: LE ISTRUZIONI DI MONTAGGIO SARANNO PRESTO DISPONIBILI IN ITALIANO: WWW.MATROMARINE.COM/OUR-PRODUCTS

IMPORTANT: LES INSTRUCTIONES DE MONTAGE SERONT DISPONIBLES BIENTOT AUSSI EN FRANCAIS: WWW.MATROMARINE.COM/OUR-PRODUCTS

lA INSTRUTIONES PARA E MONTAJES ESTARAN LISTAS EN LA MAS BREVIDAD POSIBLE EN ESPANOL : WWW.MATROMARINE.COM/OUR-PRODUCTS