33

START-UP & ADJUSTMENTS

Pre-Start Check List

√

Verify the polarity of the connections are correct, the

line voltage power leads are securely connected and

the furnace is properly grounded.

√

Verify the thermostat wires (R, W, Y, & G) are securely

connected to the correct leads on the terminal strip of

the circuit board.

√

Verify the gas line service pressure does not exceed 10.0

inches of W.C., and is not less than 4.5 inches W.C. for

natural gas. For LP gas the line service pressure must

not exceed 14 in. W.C., and must not be less than 11.0

in. W.C.

√

Verify the roll-out and manual reset switch is closed. If

necessary, press the red button to reset a switch. DO

NOT install a jumper wire across a switch to defeat its

function. If a switch reopens on startup, DO NOT reset

the switch without identifying and correcting the

fault condition

.

√

Verify the blower door is in place, closing the door switch

in the line voltage circuit.

√

Verify the gas line has been purged and all connections

are leak free.

Start-up Procedures

Do not perform these steps until all of the checks in the

previous steps have been completed:

1. Set the thermostat to the lowest setting.

2. Turn off all electrical power to the furnace.

3. Follow the Operating Instructions on the label attached

to the furnace.

4. Set the thermostat above room temperature and verify

the Operating Sequence (

5. After 5 minutes of operation, set the thermostat below

room temperature and verify steps 9 & 10 of the

Operating Sequence.

one stage of heating and the second furnace to ignite

for the second stage of heating.

3. Refer to

thermostat connections. The C connection must be

made between the twinned furnaces to ensure proper

performance.

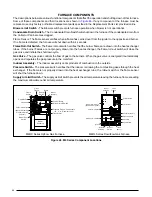

Grounding

WARNING:

To minimize personal injury, the furnace cabinet

must have an uninterrupted or unbroken

electrical ground. The controls used in this

furnace require an earth ground to operate

properly. Acceptable methods include electrical

wire or conduit approved for ground service.

Do not use gas piping as an electrical ground!

Example:

• Time for 1 revolution of a gas meter with a 1 cubic

ft dial = 40 seconds.

• From

• Local heating value of the gas (obtained from gas

supplier) = 1,040 Btu per cubic ft.

• Input rate = 1,040 x 90 = 93,600 Btuh.

Verifying & Adjusting Input Rate

IMPORTANT NOTE:

The input rate must not exceed the rate shown on the

furnace rating plate. At altitudes above 2,000 feet, it

must not exceed that on the rating plate less 4% for

each 1,000 feet.

The input rate must be verified for each installation to

prevent over-firing of the furnace. To determine the exact

input rate, perform the following procedures:

1. Shut off all other gas fired appliances.

2. Start the furnace and run it for at least 3 minutes.

3. Measure the time (in seconds) required for the gas

meter to complete one revolution.

4. Convert the time per revolution to cubic feet of gas per

.

5. Multiply the gas flow rate in cubic ft per hr by the heating

value of the gas in Btu per cubic ft to obtain the input

rate in Btuh. See example.

6. The manifold pressure must be set to the appropriate

value for each installation by a qualified installer, service

agency or the gas supplier. See

Verifying & Adjusting Temperature Rise

Confirm the temperature rise through the furnace is

within the limits specified on the furnace rating plate. Any

temperature rise outside the specified limits could result

in premature failure of the heat exchanger.

1. Place thermometers in the return and supply air stream

as close to the furnace as possible. The thermometer on

the supply air side must be shielded from direct radiation

from the heat exchanger to avoid false readings.

2. Adjust all registers and duct dampers to the desired

position and run the furnace for 10 to 15 minutes before

taking any temperature readings. The temperature rise

is the difference between the supply and return air

temperatures.

For typical duct systems, the temperature rise will fall

within the limits specified on the rating plate with the

blower speed at the factory recommended setting. If the

measured temperature rise is outside the specified limits,

it may be necessary to change the speed of the blower.

NOTE: Lowering the blower speed will increase the

temperature rise and a higher blower speed will decrease

the temperature rise.

The furnace is equipped with a multi-speed motor. Heating

and cooling speed selection is made by moving the switch

on the integrated control inside of the furnace.

Содержание M4RC-072D-35C

Страница 47: ...47...