13

Bottom Panel Removal

The steps listed below describe how to remove the bottom

panel from the furnace. See Figure 12.

1. Remove the door (1) from the blower compartment.

2. Disconnect the blower motor wiring harness (2) from

the control board.

3. Remove two screws (3) securing the blower assembly

(4) to the furnace.

4. Carefully pull the blower assembly (4) out thru the

front of the furnace.

5. Remove all screws (5) securing bottom panel (6) to

bottom of furnace and front brace (7).

6. Lift up and slide bottom panel (6) out through front of

furnace.

7. Reinstall the blower assembly (4) in reverse order.

6

7

5

1

2

3

4

Figure 12. Bottom Panel Removal

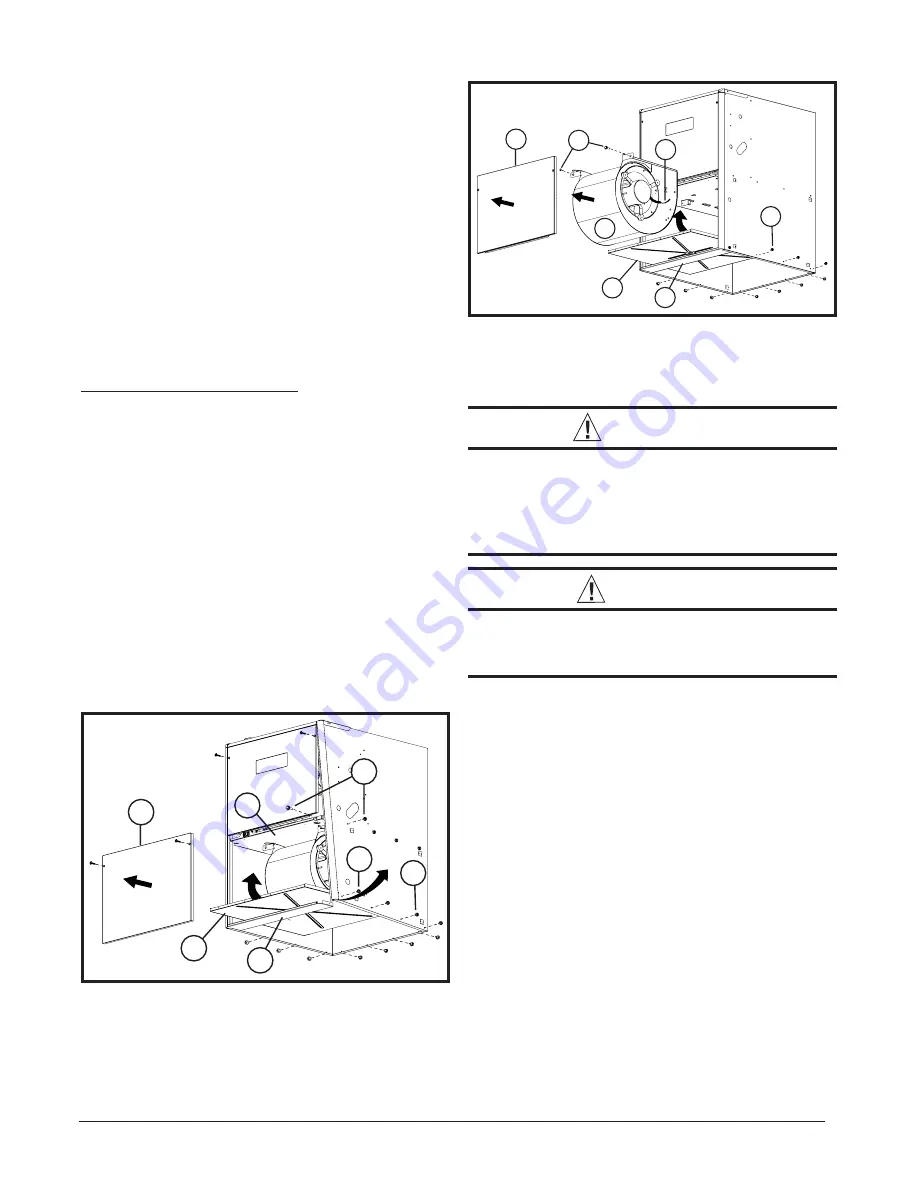

Alternate Bottom Panel Removal

If the bottom panel cannot be removed using the previous

instructions, the steps below are an alternate method for

removing the bottom panel. (See Figure 13).

1. Remove the door (1) from the blower compartment

2. Remove all screws securing the bottom panel (2) to

the front brace (3).

3. Remove two screws (4) securing the furnace cabinet

to the blower deck (5).

4. Remove all screws (6) securing the furnace cabinet

to the bottom panel (2).

5. Remove the screw (7) securing the bottom corner of the

furnace cabinet to the front brace (3).

6. Carefully spread the bottom corner of the furnace

cabinet outwards while sliding the bottom panel (2)

out through the front of the furnace.

7. Reassemble the furnace in reverse order.

Inducer Assembly Rotation

WARNING:

Inducer rotation must be completed before

the furnace is connected to gas and electric. If

both utilities have been connected, follow the

shutdown procedures printed on the furnace

label and disconnect the electrical supply.

CAUTION:

It is good practice to label all wires prior

to disconnection. Wiring errors can cause

improper and dangerous operation.

1. Disconnect the electrical harness (1) from the inducer

assembly (2). See Figure 14, page 14.

2. Remove the inducer assembly ground wire (3) from

the blower deck (4) or door.

3. Remove three screws (5) securing the inducer

assembly (2) to the header box (6).

4. Rotate the inducer assembly (2) to its new position.

5. Secure the inducer assembly (2) to the header box

(6) by reinstalling the three screws (5). If the inducer

assembly is rotated to the left or right side of the

furnace, use the extra screw provided in the parts

package.

6. Remove the cabinet plug (7) from side of furnace and

reinstall in hole on opposite side of cabinet.

7. Install in-line drain assembly and tubing.

8. If applicable, install the condensate drain as shown

in Figures 27 - 29 (pages 31 - 33).

9. Reconnect the electrical harness (1) to the inducer

assembly (2).

10. Reconnect the inducer assembly ground wire (3) to

the blower deck (4) or door.

11. Verify operation as detailed on the furnace label.

Figure 13. Alternate Removal Method

1

4

2

7

3

6

5